china bag packaging manufacturers

custom bag packaging china bag packaging manufacturers

Custom bag packaging refers to designing and creating bags tailored to the specific needs and preferences of a particular customer or brand. There are several different types of custom bag packaging, each with unique features and benefits.

Flexible Packaging

Flexible packaging is a custom bag packaging that uses flexible materials such as plastic, foil, and paper to create bags that can be easily folded, rolled, or flattened. This type of packaging is ideal for products that need to be shipped or stored in small spaces, as it takes up less room than traditional rigid packaging. Flexible packaging is also lightweight and easy to handle, making it a popular choice for food, beverage, and personal care products.

Stand Up Pouches

Stand-up pouches are flexible packaging with a bottom gusset and a stand-up design. This allows the pouch to stand upright, making it easy to display and access the product inside. Stand-up pouches are commonly used for food and beverage products, but they can also be used for other products such as health supplements, pet food, and personal care items.

Retort Pouches

Retort pouches are a type of flexible packaging that is designed to withstand the high temperatures and pressures of retort sterilization. This makes them ideal for packaging products that require long shelf life, such as canned goods, ready-to-eat meals, and soups. Retort pouches are made from a combination of plastic, aluminum, and paper, which provide the necessary barrier properties to protect the product inside.

Vacuum Pouches

Vacuum pouches are a type of flexible packaging designed to remove the air from inside the pouch and create a vacuum seal. This helps to extend the product’s shelf life by slowing down the growth of bacteria and other microorganisms. Vacuum pouches are commonly used for food products such as meats, cheeses, and seafood, but they can also be used for different types of products such as electronics and medical devices.

Rigid Packaging

Rigid packaging is a type of custom bag packaging that uses materials such as glass, metal, and plastic to create stiff bags that do not bend easily. This type of packaging is ideal for products that require more protection or are more fragile. Rigid packaging is also more durable, and it is often used for products that are heavy or have sharp edges.

Clamshells

Clamshells are a type of rigid packaging that is made from a hinged plastic container. They are designed to hold a product in place securely, and they are often used for products that are fragile or have sharp edges. Clamshells are also ideal for products that require more protection, such as electronics, toys, and personal care items.

Blister Packs

Blister packs are a type of rigid packaging that consists of a plastic blister that is sealed to a card or paperboard backing. They are commonly used for small consumer goods such as toys, batteries, and small electronic devices. Blister packs provide a high level of product visibility and offer a high level of protection for the product inside.

Other types of custom bag packaging include:

Zip lock bags

Drawstring bags

Tote bags

Garment bags

Foldable bags

etc.

In conclusion, custom bag packaging can be divided into two main categories: flexible and rigid. Each type of custom bag packaging has unique features and benefits, and the kind of packaging you choose will depend on your specific needs.

Each type of custom bag packaging has its advantages and disadvantages, and choosing the right one for your product will depend on the product itself and its intended use. It’s essential to consider the materials, shape, size, printing, and other factors when choosing custom bag packaging.

Custom packaging bags are a type of packaging solution designed and manufactured to meet the specific needs and requirements of a particular product or brand. These bags are often used for packaging food, cosmetics, electronics, and other consumer goods.

Advantages of Custom Packaging Bags

Brand Recognition: Custom packaging bags can be designed with a company’s logo, colors, and other branding elements, helping to increase brand recognition and visibility.

Protection: Custom packaging bags can be designed to provide a high level of protection for the product inside, helping to ensure that it reaches the customer in good condition.

Convenience: Custom packaging bags can be designed with features such as handles, zippers, and other closures that make them easy to use and transport.

Sustainability: Custom packaging bags can be made from eco-friendly materials, such as biodegradable or compostable materials, helping to reduce the environmental impact of packaging.

Cost-effective: Custom packaging bags can be designed to be cost-effective and provide a good return on investment for the company.

Design and Manufacturing of Custom Packaging Bags

Design: The design of custom packaging bags is typically done by a team of graphic designers who work with the client to create a plan that meets their specific needs and requirements.

Material Selection: The selection of materials for custom packaging bags is an important consideration. Common materials include plastic, paper, and fabric.

Printing: Custom packaging bags are often printed using flexography, digital printing, or screen printing techniques.

Finishing: Custom packaging bags may be finished with additional features such as lamination, gloss, or matte finish.

Quality control: The manufacturing of custom packaging bags is subject to strict quality control procedures to ensure that the bags meet the client’s specifications and are free from defects.

In summary, custom packaging bags are a versatile and cost-effective solution for packaging various products. These bags can be designed to meet specific needs and requirements and can help to increase brand recognition and protect the product inside. They can also be made from eco-friendly materials, helping to reduce the environmental impact of packaging.

Bag type selection

Stand up bag

Stand-up bags are commonly used in food packaging, such as: nut packaging, retail packaging, pet food packaging, etc.

zipper bag

Zipper bags are bags that can be repeatedly sealed by pressing the zipper to LDPE and high-pressure linear LLDPE by blow molding heat-cutting machine bags.

stand up bag with zipper

Zippered stand up bags are one of the best display packaging options for bulk items. It is a type of stand-up bag and can be sealed perfectly with zipper closure to keep all products as tight as possible.

Custom beverages food packaging materials

Pet food packaging bag production materials are mainly as follows.

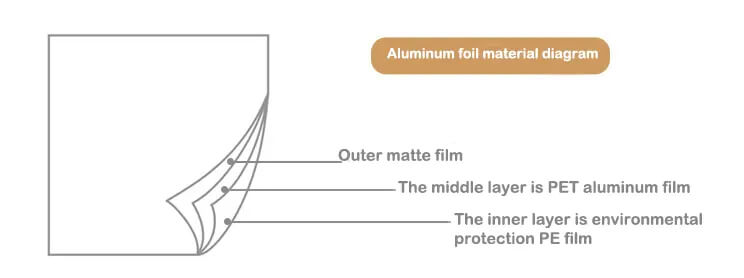

1.First layer material: PA,PET,BOPP,MATT OPP

2.Intermediate material:PET,PA,VMPET,AL,KRAFT PAPER

3.The last layer material:PE,CPP,RCPP