Custom Pharmaceutical & Medical industrials packaging

Custom Pharmaceutical & Medical Packaging

Ewaybag provides customized packaging services for medical, healthcare, and pharmaceutical products, including pharmaceutical foil pouches, stand-up pouches, zipper pouches, mask pouches, etc.

Medical products have strict requirements for hygiene, light shielding, and sealing effectiveness.

We also use superior multi-functional films to complete the manufacturing of medical product packaging, suitable for medical device packaging, etc.

Our packaging materials are not only non-toxic, tasteless, safe, and hygienic, but also have passed many certifications and can be in direct contact with medicines so that consumers can rest assured.

For customers with anti-counterfeiting needs for packaging, we have ink anti-counterfeiting technology to offer to our customers. Ink anti-counterfeiting technology is a widely used anti-counterfeiting technology in the pharmaceutical packaging industry.

This anti-counterfeiting technology mainly adds particular substances to ordinary ink, connects materials, and becomes special printing ink through a unique process.

The characteristics of this type of anti-counterfeiting technology are simple implementation, low cost, good concealment, bright colors, and convenient inspection.

Advantages of customized Pharmaceutical & Medical packaging bags

Bag type selection

1.three-sided sealed food packaging bag is a common food packaging bag type.

2.stand-up food packaging bags (stand-up zipper bags), stand-up pouch bag type, can stand independently on the container, showing promising results.

3. the seal organ food packaging bag, bag square three-dimensional, then the three-sided bag capacity, beautiful shape pattern.

4. eight sides seal food packaging bags. Stand-up pouches developed based on the bottom square can be upright; the container showcase effect is stunning.

5. Suction mouth bags. The bag type is convenient for transportation and storage. It is the first choice for packaging liquids, powders, and other products.

Stand up bag

Stand-up bags are commonly used in food packaging, such as: nut packaging, retail packaging, pet food packaging, etc.

zipper bag

Zipper bags are bags that can be repeatedly sealed by pressing the zipper to LDPE and high-pressure linear LLDPE by blow molding heat-cutting machine bags.

stand up bag with zipper

Zippered stand up bags are one of the best display packaging options for bulk items. It is a type of stand-up bag and can be sealed perfectly with zipper closure to keep all products as tight as possible.

Features and Options (Add-Ons)

Round hanging hole

Portable hanging hole

Ergonomic handles

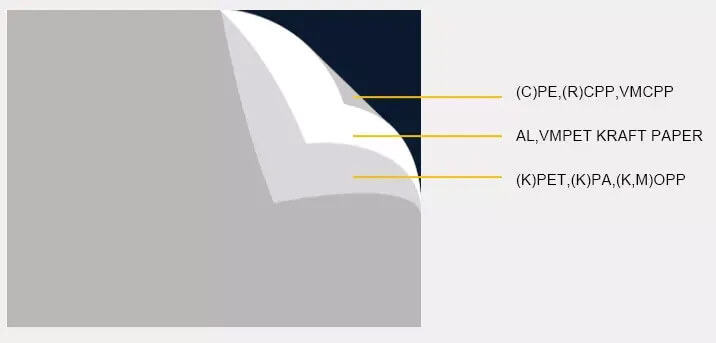

Custom Pharmaceutical & Medical packaging materials

Ewaybag selected lighter materials, non-toxic and tasteless, health and safety, no residue, beautiful and generous color, and can have a particular compressive strength and plasticity in the packaging characteristics,

it can resist wear and tear, extend shelf life, and other factors.

PET,AL,PE/PET,NY,AL,CPP