Custom Health & Beauty industrials packaging

Custom Health & Beauty Packaging

The health and beauty market has continued to grow in recent years, and the demand for products has driven the growth of the health and beauty packaging market. Ewaybag offers custom printing and packaging solutions

that match the aesthetics, high quality, and brand fit that companies in the health and beauty industry need to attract more consumers.

Our flexible packaging is made of environmentally friendly materials, suitable for a wide range of sizes and shapes, and ideal for aqueous solutions, powders, and various cosmetic products.

Our high-quality materials make our packaging products have good airtight sealing performance, which can protect your products nicely, and have anti-puncture, flexible space suitable for travel carry.

With 20 years of experience manufacturing bags, we can provide you with high-quality health and beauty packaging.

Advantages of customized Health & Beauty packaging bags

Bag type selection

1.three-sided sealed food packaging bag is a common food packaging bag type.

2.stand-up food packaging bags (stand-up zipper bags), stand-up pouch bag type, can stand independently on the container, showing promising results.

3. the seal organ food packaging bag, bag square three-dimensional, then the three-sided bag capacity, beautiful shape pattern.

4. eight sides seal food packaging bags. Stand-up pouches developed based on the bottom square can be upright; the container showcase effect is stunning.

5. Suction mouth bags. The bag type is convenient for transportation and storage. It is the first choice for packaging liquids, powders, and other products.

Stand up bag

Stand-up bags are commonly used in food packaging, such as: nut packaging, retail packaging, pet food packaging, etc.

zipper bag

Zipper bags are bags that can be repeatedly sealed by pressing the zipper to LDPE and high-pressure linear LLDPE by blow molding heat-cutting machine bags.

stand up bag with zipper

Zippered stand up bags are one of the best display packaging options for bulk items. It is a type of stand-up bag and can be sealed perfectly with zipper closure to keep all products as tight as possible.

Features and Options (Add-Ons)

Round hanging hole

Portable hanging hole

Ergonomic handles

Custom Health & Beauty packaging materials

Packaging materials for the health and beauty industry have diversified to include plastic, paper, glass, and many other options.

As a professional packaging manufacturer, we can provide customized production services with our customers’ materials.

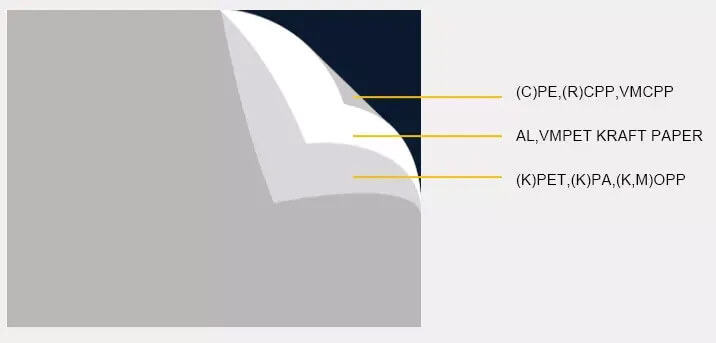

Here is the structure of plastic materials:

PET/PE, PET/MPET/PE. PET/FOIL/PE. KPET/PE . HSBOPP/CPP. NYLON/PE