3 Side Seal Pouches custom Printed and zipper

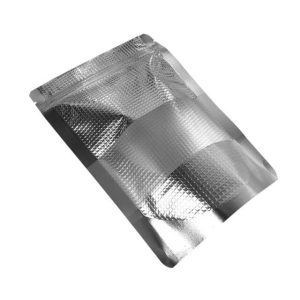

Three side seal food packaging bags are sealed on three sides, leaving only one opening for users to install the product. Three-sided sealed food packaging bags are a standard bag-making method. Three-sided filled bags are airtight, single-sided three-sided sealed bags with a zipper combination, and three-sided sealed food packaging bags with a zipper bag combination, keeping the product fresh, moisture-free, and oxygen-free.

- Custom printing, badges are available

- Made of food-grade material

- Low minimum order quantity

- 3 side seal stand up pouch

- 30% discount on the first order

Three side Seal Pouch Type

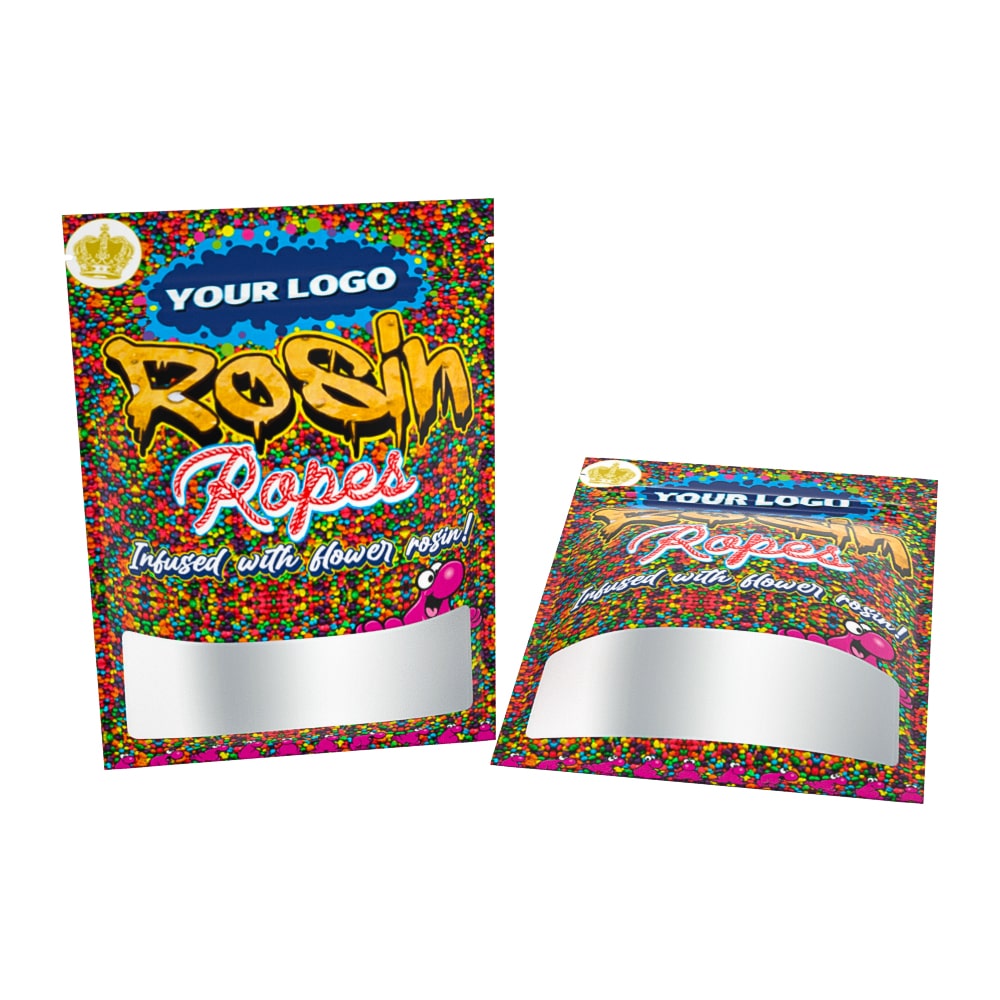

Custom Print 3 Side Seal pouch

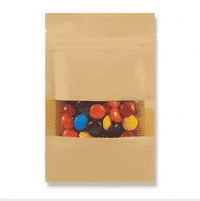

3 side seal pouch with window

3 side seal flat pouch with zipper

3 side seal packaging

3 side seal pouch manufacturer

Ewaybag provides 3 seal bag packaging for Amazon resellers, food manufacturers, and brands.

A 3 side seal pouch is a bag that is sealed on three sides; while it has only one opening, leaving only one space for Ewaybag to use, we can customize the bag size, printing, and emblem according to customer needs.

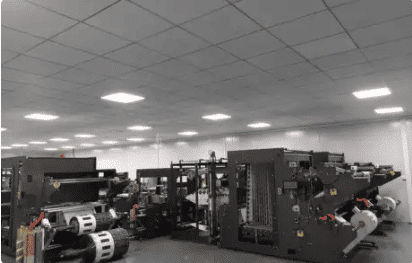

Ewaybag offers a wide range of bags for both food and non-food industries. We have digital and gravure printing machines, up to nine production lines.

These facilities allow us to mass produce and ship our products. Even with high production capacity, we can guarantee the quality of our products thanks to our advanced manufacturing technology.

As a 3 side seal pouch factory, we offer competitive prices and design services to ensure every customer can get the three-side-seal bag to their satisfaction.

The feature of three side seal packaging bags

- The three-side-seal bag has good air tightness, excellent moisturizing performance, and sealing performance.

- It has a high degree of barrier and deficient oxygen and moisture permeability.

- It has a solid ability to prevent moisture and mildew.

- It is bright and beautiful and non-toxic and tasteless.

- It has a high space utilization rate.

3 Side Seal Pouch packaging bags applications

- Plastic food packaging bags,

- vacuum nylon bags,

- rice packaging bags,

- tea bags,

- candy bags,

- powder bags,

- automatic packaging machines,

- paper plastic bags,

- bowl seal film,

- shaped bags,

- rice bags,

- cosmetic bags,

- mask eye mask bags,

- medicine bags

- pesticide bags.

- anti-static bags,

- film rolls,

- plastic bags.

- Sealed packaging for various consumables such as printers, copiers

Customized three side seal flat pouches with optional features

- Size can be customized to meet customer needs from 10g to 20g to 1KG 2KG

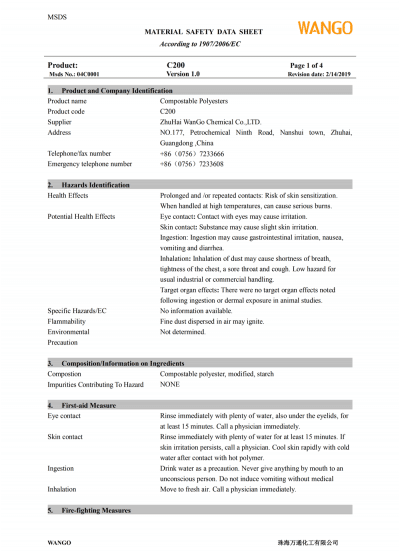

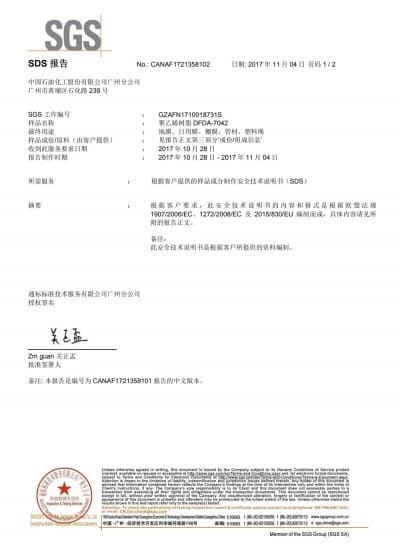

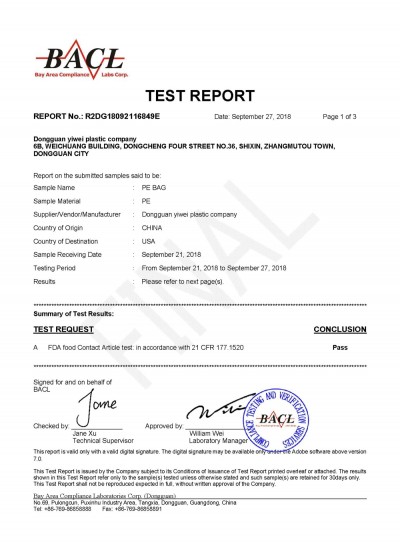

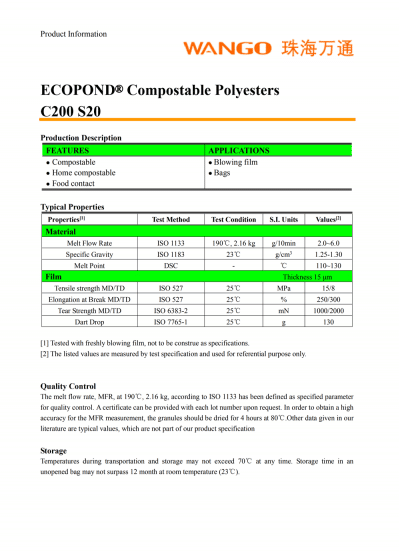

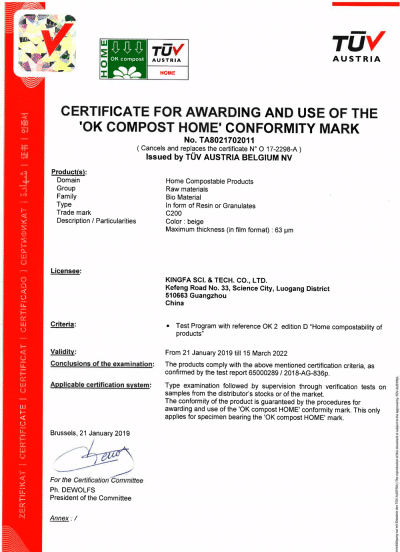

- Material: PET, CPE, CPP, OPP, PA, AL, KPET in double or multi-layer structure with food-grade certification

- Surface effects Matte, laser film, glossy, kraft, tactile, paper, demetallized, unprinted, and registered matte finishes are available.

- Printing: digital or gravure printing, printing colors up to 9 MOQ 500PCS

- Customized accessories: repeat closure zipper, easy tear opening, product view window, rounded corners, euro slot

- Competitive price: first order discount, save your packaging cost

Re-sealable zipper

Easy-open tear opening

Hanging holes for shelf display

Rounded corners

Product display windows

Customize your 3 Side Seal flat pouches

Ask for Free Sample or Custom 3 Side Seal Pouch Now!

3 Side Seal Pouch advantage

1

Save money for you

You can get 30% off your first order and apply for a manager’s discount for larger purchases.

2

Fast shipping

Same day delivery for orders placed from stock, 7 working days for custom products

3

Fast speed

Customers can choose from dozens of bag types, such as stand-up, three-side-seal pouches, suction nozzle pouches, etc.

4

FDA approved materials

Environmentally friendly food grade material, FDA-approved, safe and hygienic.

5

Customized Printing

Customers can choose digital printing or gravure printing; the pattern is customized according to customer needs.

6

Customized Size

No matter 1 gallon or 3.5G, Custom size according to customer’s requirement

7

Design Service

Realize all customer’s ideas for bags, brand customization service

8

Perfect after-sales service

We have professional colleagues in charge of after-sales service to solve all kinds of packaging bag problems for our customers.

Customization 3 Side Seal Pouch process

Request a Quote

Call or email us, and we’ll get back to you within 6 hours.

Approval of artwork

You can provide pictures or samples, and our professional designers will communicate with you to achieve your desired design.

Printing and Production

Our digital and gravure printing process ensures that any design you require can be printed in as little as three days.

Quality Check

Every bag we want is a work of art; finding and dealing with bad bags is our best promise to our customers.

Logistics Express

We will deliver your bags to the place you tell us in time to ensure that you can receive your products in time.

China 3 Side Seal Pouch

China 3 side seal pouch Introduction

A China 3 side seal pouch is a type of flexible packaging material widely used in the food industry for packing and preserving various products. It is characterized by its three-sided sealing structure, which provides an airtight and leak-proof barrier for the contents of the pouch. The pouch is made from various materials, including plastic films, paper, and foil, and can be produced in different sizes and shapes to meet the specific needs of other products.

Advantages of China 3-Side Seal Pouch

There are several benefits to using a China 3 side seal pouch for packaging products. One of the main advantages is that it provides excellent protection for the bag’s contents. The three-sided sealing structure ensures that the contents are entirely sealed off from the outside environment, preventing the ingress of air and moisture that can cause spoilage and degradation. This makes the pouch ideal for preserving the quality and shelf life of products such as food, beverages, and pharmaceuticals.

Another advantage of the China 3 side seal pouch is its convenience and ease of use. The bag is designed with a seal that can be easily opened and closed, allowing consumers to access the pouch’s contents easily. It is also lightweight and easy to carry, making it convenient for on-the-go consumption.

In addition, the China 3 side seal pouch is a cost-effective packaging solution. It can be produced at a lower cost than other packaging materials, such as cans and bottles, and requires less energy and resources to manufacture. This makes it an environmentally friendly option for packaging products.

Types of China 3 Side Seal Pouch

There are several types of China 3 side seal pouches available, depending on the material used to make the pouch and the product’s specific needs.

Plastic Film Pouch: This type of pouch is made from plastic film and is commonly used for packing food and beverages. It is available in different thicknesses and can be printed with graphics and text for branding and marketing purposes.

Paper Pouch: This type of pouch is made from paper and is commonly used for packing coffee, tea, and other dry products. It is more environmentally friendly than plastic pouches, but it may provide less protection for the contents than plastic pouches.

Foil Pouch: This type of pouch is made from foil and is commonly used for packing products that require high levels of protection from light, oxygen, and moisture. It is more expensive than plastic and paper pouches but provides excellent protection for the contents.

Features of China 3 Side Seal Pouch

The China 3 side seal pouch has several features that make it a suitable packaging material.

Sealing Structure: The pouch has a three-sided sealing structure that provides an airtight and leak-proof barrier for the contents. This prevents the ingress of air and moisture, ensuring that the contents remain fresh and of high quality.

Customization: The pouch can be customized in size, shape, and material to meet the specific needs of different products. This allows companies to package their products in a way suitable for their target market and unique product characteristics.

Printability: The pouch can be printed with graphics and text, allowing companies to use it for branding and marketing purposes. This can help differentiate their products from competitors and increase brand awareness.

Conclusion

The China 3 side seal pouch is a popular and effective packaging material widely used in the food industry to preserve and protect various products. Its three-sided sealing structure, convenience, and ease of use.