Custom Beverages industrials packaging

Custom Beverages Packaging

Ewaybag offers a wide range of packaging solutions for the food and beverage industry; whether it is for solid food or liquid beverages, we have many years of experience in manufacturing.We have a wide range of beverage bags, including stand up pouches, flat bottom bags, and aluminum foil bags.

Our beverage packaging bags are designed to prevent damage caused by biological and other organisms. The packaging can isolate the food from the environment and prevent outside microorganisms and other organisms from invading the food.

The use of sealed packaging with good isolation performance and other anti-bacterial preservation methods can extend the shelf life of beverages.

Brands That Trust Us

Types of Liquid Packaging Bags

baby food pouch manufacturer

juice spout pouch

spout pouch supplier

Aluminium Spout Pouch

Liquid Pouch with Spout

liquid detergent pouch

laundry detergent bag

aluminium foil spout pouch

Liquid Pouch Bag with Spout

Transparent Spout Pouch

Spout Pouch Detail

Spout mouth with high quality cap to prevent oxidization

Self-supporting bottom, stable, not easy to fall down

Multiple designs and logos can be printed

Neat edge sealing, strong sealing, no bag bursting

Advantages of customized beverages packaging bags

- Packaging materials made of food-grade materials, environmentally friendly, and non-toxic, can directly touch the beverage.

- Our beverage packaging products prevent chemical deterioration. In direct light, fluorescent light, or a high temperature, aerobic environment, the pigments and fats contained in the beverage will undergo various chemical reactions.

- Prevent physical deterioration. Solid beverages tend to absorb moisture from the environment and deteriorate.

- The structure is airtight, and the bag can stand, roll up, fold, flatten, and be easily carried.

- It is not easy to break (safety), foldable after use, recyclable; easy to use like putting tap water, and switch freely

- It is not easy to break because it is BPA-free, with acid resistance, abrasion resistance, good transparency, strong stain resistance, and non-fading.

- Stand Up, Zip Lock, Zipper Top, Moisture Proof, Strong Sealing, Clear Window

- OEM custom print available, up to 9 colors

How to Order Liquid Packaging Bags

1

Send Inquiry

Tell us what you need via email, WhatsApp or online chat!

2

Approve design

Determine the bag design file, including printing pattern, size, quantity, etc.

3

Produce bags

Producing bags that meet customer requirements in our bag factory

4

Fast delivery

According to the specified time delivery, sea freight and air freight global logistics

Bag type selection

Stand up bag

Stand-up bags are commonly used in food packaging, such as: nut packaging, retail packaging, pet food packaging, etc.

zipper bag

Zipper bags are bags that can be repeatedly sealed by pressing the zipper to LDPE and high-pressure linear LLDPE by blow molding heat-cutting machine bags.

stand up bag with zipper

Zippered stand up bags are one of the best display packaging options for bulk items. It is a type of stand-up bag and can be sealed perfectly with zipper closure to keep all products as tight as possible.

Features and Options (Add-Ons)

Round hanging hole

Portable hanging hole

Ergonomic handles

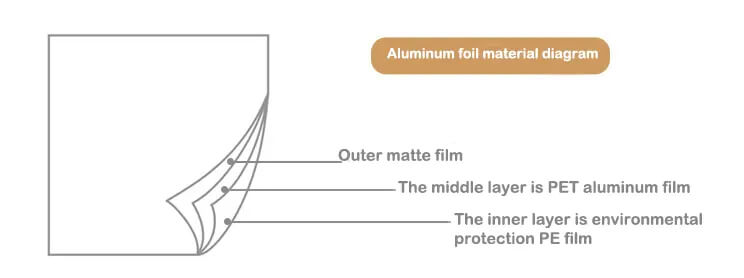

Custom beverages food packaging materials

Pet food packaging bag production materials are mainly as follows.

1.First layer material: PA,PET,BOPP,MATT OPP

2.Intermediate material:PET,PA,VMPET,AL,KRAFT PAPER

3.The last layer material:PE,CPP,RCPP

Composite flexible packaging spout pouches are widely used and occupy a significant share in food, daily chemical products, pharmaceuticals, and health care products. In these applications, the suction nozzle products are divided into three categories according to the content: powder, liquid, and liquid, with different structural designs.

For powder products, generally, 2~3 layers structure is used, such as:

PET/PE

NY/PE

BOPP/VMPET/PE

Used for packaging spices, granular sugar, toner, and other lightweight goods for three-layer material design to achieve a specific decorative effect.

Liquid products generally use 3~4 layer structure, such as:

PET/AL/PE

PET/NY/PE

PET/AL/PET/PE

PET/AL/NY/PE

For packaging salad dressings, fruit and vegetable jams, jellies, and other liquid commodities, a 3~4 4-layer material structure is chosen to ensure compliance with the physical property requirements.

Liquid products generally use 3~4 layers of material structure to ensure the transportation and use of the product as the primary goal; choose NY/NY/PE, PET/NY/PE, and other structures are mainly used for packaging daily laundry detergent, juice, beverages, and even some beverages, water and other commodities. Of course, some lightweight liquid nozzle bags also have a two-layer material structure design, such as the goods below 100ml, there will be NY/PE or PET/PE structure goods.