Packing Lamination Roll Printed Plastic Roll for Packaging

We are one of the leading laminating packaging roll film manufacturers in China, and we offer our customers a wide range of food, pharmaceutical, and pouch packaging roll film manufacturing services.

We customize roll film and pouches in various sizes and specifications according to customers’ requirements. We also use advanced gravure digital printing to give customers high-quality printing results.

Our rolls of the film mainly include PVC heat shrink film rolls, opp rolls, pe rolls, pet protective film, composite rolls, etc.

According to the material structure is divided into two-layer, three-layer, four-layer, five-layer, etc., two-layer: PET/PE, PET/CPP, OPP/CPP, OPP/PE; NY/CPP, NY/PE, PET/VMCPP, OPP/VMCPP; three-layer: PET/NY/PE, PET/NY/CPP, PET/AL/PE, PET/AL /CPP, OPP/AL/PE, PET/VMCPP/PE, OPP/VMPET/PE; four-layer have PET/AL/NY/PE, NY/AL/NY/PE, etc.

Advantages of Printed Plastic Roll for Packaging

- Automatic packaging roll film adopts a multi-layer structure and heat sealing technology; the sealing performance is usually better.

- It can effectively prevent food leakage and contamination.

- Excellent sealing and moisture resistance to protect products from damage and contamination

- Automatic food packaging roll film suits large-scale, high-efficiency automated production lines.

- It can quickly and accurately complete the food packaging process.

- Used for potato chips, frozen meat and vegetables, bagged candy, coffee, cat food and other food packaging

Flexible Packaging Film Materials

- Transparent roll film: BOPP/CPP、PET/PE、PA/PE

- Aluminized roll film:BOPP/VMCPP、PET/VMPET/PE

Custom Printed Candy Packaging Film

Advantages of Printed Plastic Roll for Packaging

Application of Candy Packaging Film

Our confectionery packaging films meet the needs of a wide variety of applications, providing the ultimate protection for food and snacks, including candies, lollipops, cookie roll wrapping, coffee beans, coffee grounds, coffee powder, tea, nuts, whey protein, pet food, snacks, and a wide range of other foodstuffs.

Confectionery packaging film materials and thicknesses

Food grade. PET, PA, PE, BOPP, CPP, VMPET, AL, PE etc.

- PET+PE

- PET+AL+VMPET+NY+PE

- PET+AL+NY+PE

- According to customer’s requirement

Quality of candy roll film

Our candy food packaging films have passed many certifications, including FDA, ISO, and so on, which can guarantee the quality of our products well. Food grade raw materials and professional guarantee technicians. There are a variety of ways to ensure the quality of customers’ food packaging.

Custom Printed Roll Stock Film

Flexible Printing film

Custom Printed Plastic Film Roll

Ice Cream Bar film roll

Wholesale Sachet film

Chip Film Roll

sachet packaging

Sachet packaging factory

Customize Your Printed Plastic Roll for Packaging

Ask for Free Sample or Printed Plastic Roll Film Film Now!

Please fill in the following form correctly so that our can contact you

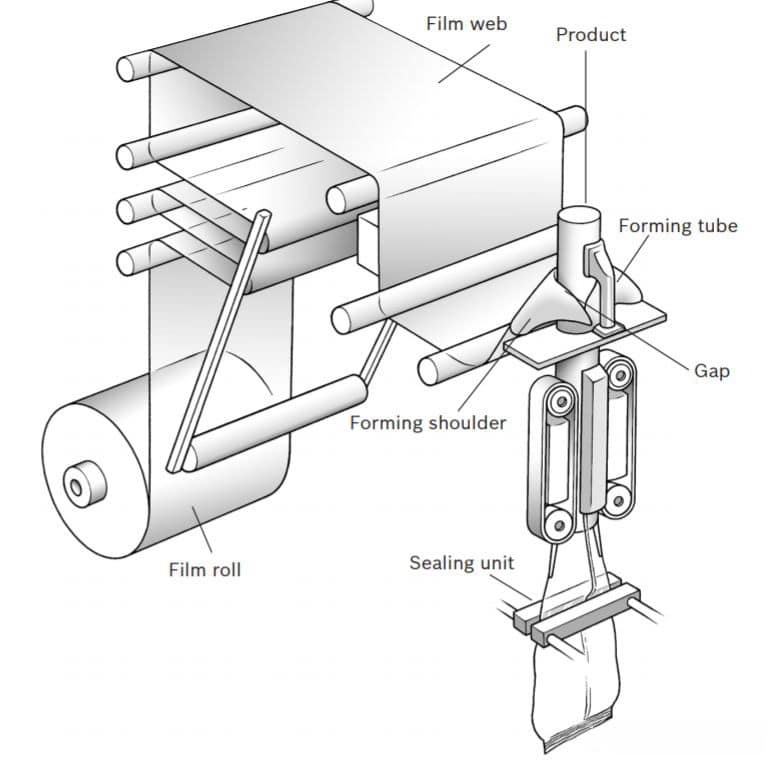

Working principle of roll film packaging

In the bag industry, roll film is divided into two meanings. One refers to the raw material of the bag roll film, which is made of a single layer of material, such as CPP, PE, or PET.

OPP, kraft paper, aluminum foil, and so on are rolled-up films. Another bag is printed roll film, the raw material after printing. Composite, rolled-up film is also called composite roll film or printed roll film.

Called composite roll film or printing roll film, it is made of bags from the previous process and is commonly used in small packages, such as candy, coffee powder, honey, etc. Vacuum Packaging Bags, Tea Packaging Bags

Business difference

Single-layer roll film manufacturers can only produce transparent plastic film and can not directly produce packaging bags from the upstream of the bag manufacturer, which is the raw material for bags.

Pake composite (printing) roll film manufacturers are transparent, non-printed roll film, with a series of production processes to make (printing) roll film.

Based on this increase in the bag-making process, you can produce a variety of composite packaging bags, including casual food bags and large bags of food and beverage packaging.

These include casual food bags, rice bags, tea bags, vacuum bags, aluminum foil bags, high-temperature cooking bags, and mask bags.

We are a professional film manufacturer. We can provide customers with their own printed film to improve the quality of their packaging.

Custom Sachet Film

Step 1:

Get a quote

Please send an inquiry on our website and get back to the client within 1 hour for a quick quote.

Step 2:

Develop your art

Customers provide their design, or we design for you free of charge until customers are satisfied.

Step 3:

Size and Configuration

Determine film details, including size, printing, quantity, etc.

Step 4:

Packaging film production

20 years of experience in the production of your film, with attention to every detail of the bags

Step 5:

Delivery of packaging film to customers

Fast delivery with global logistics, fast delivery, and perfect after-sales service