china professional flexible packaging film manufacturer

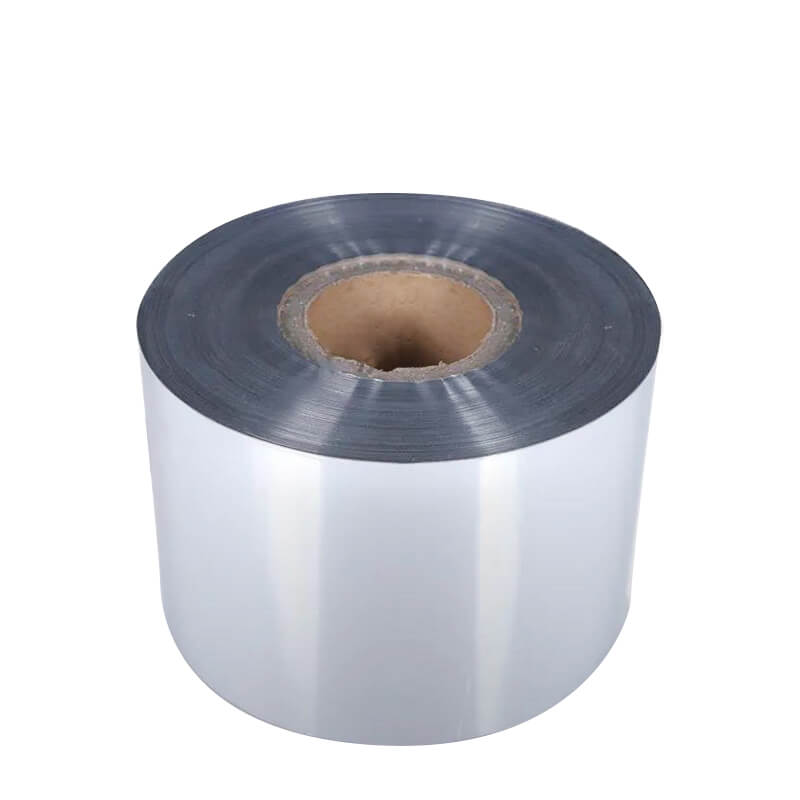

We are a leading packaging film manufacturer from China. We not only produce all kinds of stand-up pouches, aluminum foil pouches, and other laminated food packaging bags, but flexible packaging film is also one of our main products.

With years of packaging technology accumulation, the quality of our packaging film is no different from that of the bag manufacturers in Europe and North America, and even better in some places. But we have a more significant price advantage than them.

Choosing the correct type of packaging film for your product can be a challenge. Many flexible packaging manufacturers offer standard products in flexible packaging materials. With our customized packaging films, custom packaging films can help you enhance your brand.

Flexible Packaging Film Type

- pvc shrink film roll film.

- opp roll film.OPP PET PA PE CPP VMPET AL and other laminated film

- pe film rolls.

- pet protective film,ice candy plastic roll

- laminated film rolls,snack packaging film

Packaging Film Parameters

- Printing layout: Gravure printing in nine colors

- Packaging film specifications: width 2~50cm; thickness 0.8 silk~30 silk; length arbitrary

- Material:PET/OPP/PA/PE/Aluminized/Aluminium foil/Kraft paper etc.

- Sealing film roll, cup sealer film,cup sealer film printing,ustom sealing film

Custom Printed Packaging Film Roll

flexible packaging film manufacturer

laminated food packaging

flexible packaging films

Plastic Flexible Packaging

printed film packaging

laminated film for food packaging

Cookie packaging roll film

Flexible Packaging Plastic

Aluminum foil roll film

Transparent & Laminated packaging roll film

poly film packaging

Snack Packaging Roll Film

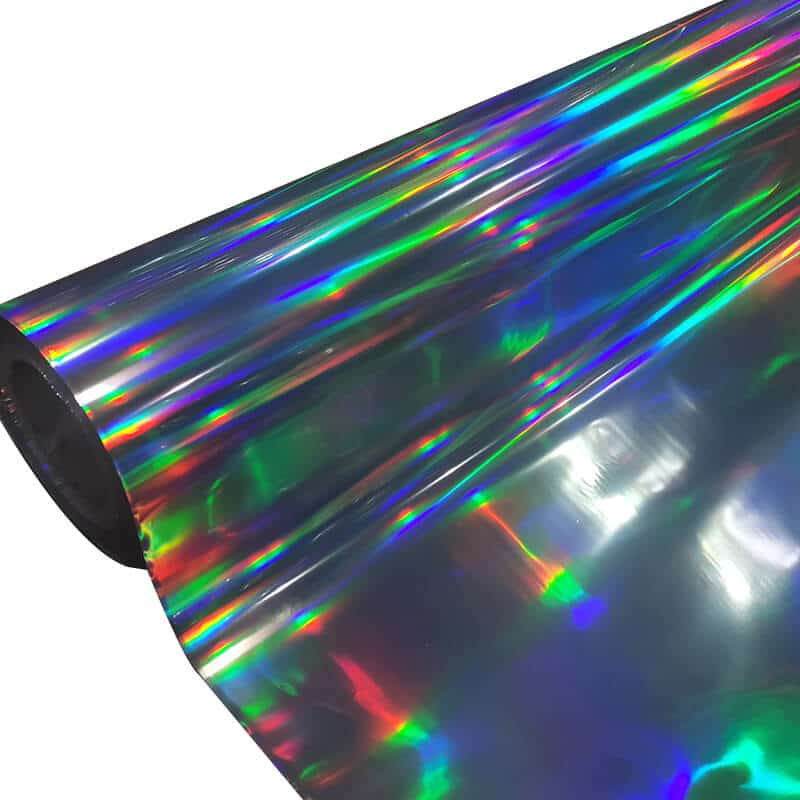

bopp holographic film

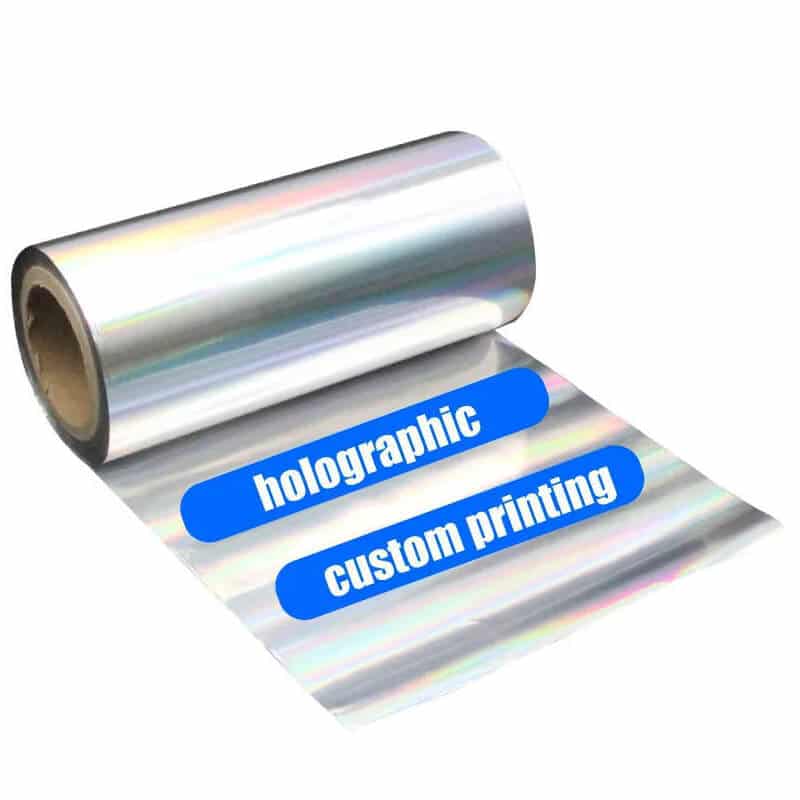

custom holographic film

holographic lamination film

Holographic Transfer Film

transparent holographic film

pet hologram film

holographic overlay film roll

Transparent Holographic Lamination Film

Tissue Paper Films

Tissue Roll Bags

poly film packaging

Snack Packaging Roll Film

Customize Your Flexible Packaging Film

Ask for Free Sample or Custom Flexible Packaging Film Now!

Please fill in the following form correctly so that our can contact you

Flexible Packaging Film Applications

The most widely used laminated roll film is made of two or more materials, which are processed by one or more lamination processes, thus constituting a composite material with specific functional characteristics. Generally, the composite material can be divided into the printing layer, active layer, and heat seal layer.

The outer layer is generally made of polyester, nylon, oriented polypropylene, paper, and other materials. In contrast, the middle layer is made of aluminum foil, aluminized film, polyester, nylon, and other materials, and the inner layer is mainly made of flowing polypropylene and polyethylene.

Our laminated roll films are widely used in packaging snack foods, frozen foods, dehydrated vegetables, spices, cooked food products, solid drinks, powders, wet wipes, and other products.

film for food packaging

packaging roll film

plastic roll printing

Composite Food-Grade Material

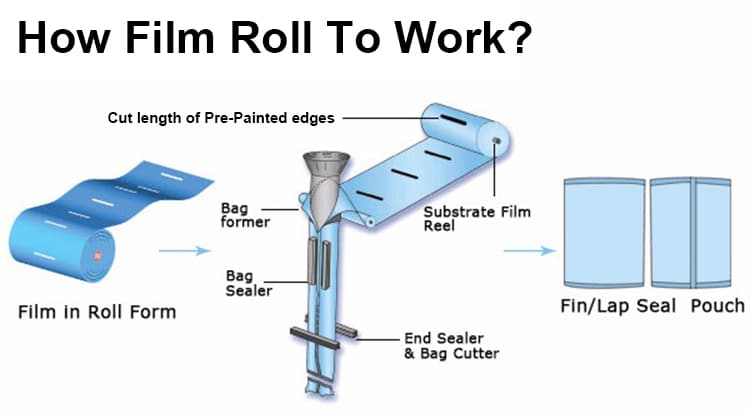

When the plastic packaging roll film is delivered to the customer, the customer needs to have their automatic filling machine, and the plastic packaging roll film completes the whole process of bag making, filling, sealing, and coding on the automatic packaging machine.

The following are standard roll film packaging machines.

Custom flexible packaging film

Step 1:

Get a quote

Please send an inquiry on our website and get back to the client within 1 hour for a quick quote.

Step 2:

Develop your art

Customers provide their design, or we design for you free of charge until customers are satisfied.

Step 3:

Size and Configuration

Determine film details, including size, printing, quantity, etc.

Step 4:

Packaging film production

20 years of experience in the production of your film, with attention to every detail of the bags

Step 5:

Delivery of packaging film to customers

Fast delivery with global logistics, fast delivery, and perfect after-sales service

Why Choose Ewaybag?

Common Automatic Packaging Roll Film Materials and Uses

Automatic wrap-around film materials include aluminum foil, aluminized, pure aluminum, two types of laminate, and easy-tear film. Each material has its characteristics. Auto wrap roll film can be divided into five categories according to the material:

- Photocatalytic inorganic antibacterial film

- Polymer antibacterial film

- Composite antibacterial film

- Inorganic antibacterial film

- Organic antibacterial film

The material of plastic roll film is similar to the plastic bags used in daily life, such as PVC shrink film, polypropylene (OPP) film, polyethylene (PE) film, PET film, composite roll film, etc.

Laminated films are suitable for vacuum packaging or general packaging of food, electronic products, chemical, pharmaceutical, tea, precision instruments, etc.

The following are standard auto-wrap roll films.

PET/PE laminated roll film

OPET/LDPE laminated film is made of polyethylene terephthalate and high-pressure polyethylene, usually called PET/PE laminated bag. This auto-wrap roll film has the characteristics of high transparency and good oxygen resistance, so it is especially suitable for inflatable packaging of bread, cakes, and other food products. In addition, the composite film has good heat and cold resistance and can also be used as bags for quick-frozen food and steamed food.

BOPP/CPP laminated roll film

BOPP/CPP laminated film comprises biaxially oriented polypropylene and unoriented polypropylene, commonly known as OPP/CPP laminated film bags. This auto-wrap roll film has high transparency among all laminated films. Compared with single-film plastic bags, the cost is higher than single-film plastic bags at the same thickness, but the hand feel is better than single-film plastic bags. Because this film has good moisture resistance, it is used in food, mainly for packing some dry food and fast food, such as cookies and instant noodles. The disadvantage is that the high temperature and cold resistance could be more suitable for food packaging, refrigeration, and high-temperature sterilization.

OPP/Polyethylene laminated roll film

BOPP/LDPE laminated film comprises biaxially oriented polypropylene and high-pressure polyethylene laminated film bags, generally called OPP/PE laminated film. This automatic wrap roll film has excellent gas and moisture resistance, which is especially suitable for packaging green tea and other products. Oil resistance is also good, so cooked food and some oil products use this composite bag packaging.