The zipper is one of the important accessories in marijuana packaging, especially child-resistant zippers, which are widely used in marijuana bags. Cannabis zipper bags as a solution for marijuana packaging

They are popular with stores, businesses, and individual consumers and are also in compliance with some state and local regulations.

There are several advantages to marijuana zipper bags:

- Keeps Cannabis Fresh: Cannabis is susceptible to moisture and air, so zipper bags keep it fresh by effectively blocking out moisture.

- Consumer-friendly: resealable zippers increase the usability and longevity of the bags, ensuring frequent use.

- Inexpensive: Zipper bags are an affordable packaging option over glass and boxes for marijuana, making them the best choice for small businesses just starting.

- Environmentally friendly: Cannabis zipper bags can be made from recyclable, compostable, and eco-friendly materials, and paper zipper bags can be used to reduce environmental pollution.

- Regulatory Compliance: Child-resistant zippers are required by many state and local laws, and using child-resistant zippers on hemp zipper bags is good protection for children.

In summary, marijuana zipper bags are one of the best choices for packaging marijuana; not only do they have a high economic value, but they also can effectively block moisture, keep marijuana fresh, and can be customized printing belongs to the enterprise design

Thus enhance the brand awareness of the product.

U.S. Law Requirements for Marijuana Bags

Packaging for marijuana goods must meet the following requirements:

Child-safe

Tamper-proof

Resealable (if more than one serving)

Opaque (if edible marijuana product)

Child-resistant packaging (CRP)

State law requires that all marijuana commodities be sold in Child Resistant Packaging (CRP), which is packaging designed to be difficult for children under the age of 5 to open.

Types of Child-Resistant Packaging

Single-Use (“Initial CRP”): The package is initially child-resistant, but once opened, it is no longer child-resistant. If used, the labeling on the package must state, “When opened, this package is no longer childproof.”

Multiple Use (“Lifetime CRP”): The package remains child-safe for its lifetime. It can be opened and closed, and it will still remain child-safe.

Zipper classification of marijuana zipper bags

Child-resistant zippers

This type of zipper bag can effectively prevent children from opening the marijuana bag; the zipper is hidden in the bag, and the zipper’s opening is hidden in the bag.

Child-resistant zipper packages are made of high-barrier, flexible material that keeps products fresh and seals in aromas while blocking out harmful outside contaminants such as moisture, oxygen, and UV rays.

Fingerprinted plastic child-resistant zipper bag

Using a complex two-way zipper or needing to press + slide to open, making it difficult for children to open easily, using BOPET +Aluminum Foil + PE structure can effectively block air, moisture and anti-odour, to keep marijuana fresh, composite legal requirements, it is a reliable child-resistant zipper bags.

Child Resistant Lock Bag

Marijuana Child Safety Lock Bags are bags specifically designed to store and protect products containing marijuana or related products to ensure that they are not easily accessible to children.

These bags are widely used in the legal marijuana market to meet relevant safety regulations.

The bag has a two-way slide lock at the zipper: it needs to be pressed and slid to unlock, and only an adult has sufficient strength and coordination to accomplish this.

Only adults have enough strength and coordination to do it. Children’s hands are not strong enough to unlock the zipper, which prevents children from opening the zipper and protects them.

MOPP/PET/AL/WMPET/PE/Customized material structure, with high strength, waterproof and tear-resistant properties and good light insulation, keep the product inside the bag fresh.

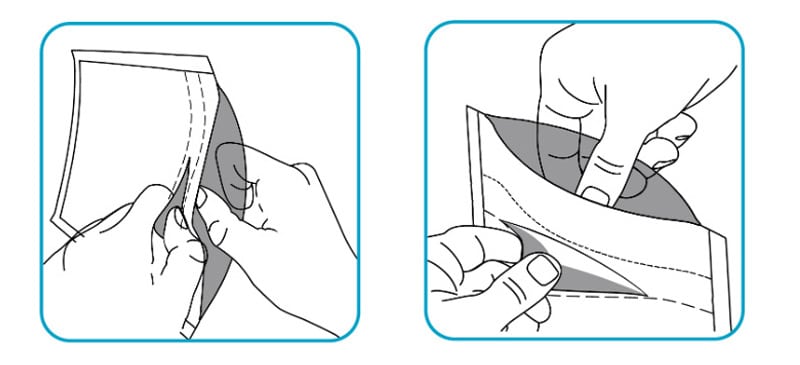

Hidden Zipper Childproof Zipper Pouch

Hidden zipper childproof zipper using the hidden structure of the zipper and complex unlocking method, increasing the difficulty of operation, designed for child protection design

Ordinary zipper bag zipper directly on the top of the bag can be opened directly to seal the bag; this childproof zipper, directly in the bag, can not be pulled; you need to use the side of the bag hidden in the

The zipper cannot be opened directly from the top of the bag; it needs to be opened with the help of a hidden puller on the side of the bag. Hidden pull tabs make it difficult for children to find and operate. Complicated unlocking steps increase safety and reduce the risk of accidental opening, thus achieving a childproof function.

Made of PET/PA/PE material, accepts customization, and can be printed with customer’s design for customers to enhance their brand of cannabis packaging.

Slider Zippers

Many simple marijuana bags require only a slider zipper like the ziplock, which is simple and easy to install for marijuana weed and requires simple packaging.

Weed Zippers

Many marijuana composite bags are made with this type of zipper. The zipper is usually inside the bag, which is sealed by the guides that bite into each other. The zipper is generally inside the bag and is sealed by the interlocking guides.

Zip of weed

Often referred to in marijuana packaging, the term zip of weed refers to the standard amount of marijuana that can be purchased for personal use, usually one ounce. And there are some marijuana unit conversions.

1 zip = 1 ounce = 28 grams

1 zip = 8 eighths (3.5 grams each)

1 zip = 4 quarters (7 grams each)

1 pound (also known as a “pizzle”) = 16 ounces = 16 zip

How do you choose the right weed zipper bags for marijuana packaging?

Choosing the right marijuana packaging bags, especially odour-resistant storage bags with zippers, can effectively maintain the freshness, privacy and security of marijuana.

Among the wide variety of weed zipper bags in the market, we, as a professional marijuana packaging manufacturer, provide the key factors of choice for customers’ reference:

1. Marijuana Packaging Bag Material:

Most of the marijuana packaging bags are made of polyester film material; the specific material is usually MOPP/PET/AL/WMPET/PE, as a professional marijuana packaging manufacturer also accept

Customized materials can do customized production for customer’s unique needs.

Our material has the effect of anti-odour and blocking air and moisture, which can effectively keep the fresh marijuana.

From an environmental point of view, we also have biodegradable and recyclable marijuana packaging bags, as well as paper-based marijuana packaging bags, so that the customers’ marijuana packaging is more environmentally friendly!

2. Choose good sealing performance of marijuana packaging

Good sealing performance is crucial for marijuana packaging; it can block the odour of marijuana, keep the freshness of marijuana, and block air moisture damage to marijuana.

Our stand-up marijuana bags are generally sealed with a zipper. After the marijuana is loaded, the top of the bag is heat-sealed to seal the marijuana further and ensure the quality of the marijuana.

Our three types of child-resistant zippers provide better protection for children and comply with local laws and regulations.

3. Choosing the right size of marijuana packaging

Common sizes of marijuana are 1g 8.5×11.5+5cm 3.5g 10×12.5+5 7g 10×16.5+6 14g 13×20.5+8 28g 15×25+8cm We’ve summarized a chart corresponding to marijuana grams and bag sizes for your reference

| Cannabis weight | Three-sided seal Sizes(cm) | Standing Bag Sizes | Remarks |

| 1g(0.035 Ounces) | 3″ x 4″ ( 7.6x 10.2 ) | 8.5×11.5+5cm | Small pouches for single, small-dose consumption |

| 3.5g(1/8 Ounces) | 4″ x 6″ (10.2x 15.2) | 10×12.5+5cm | Generally in small individual packages for short-term consumption |

| 7g(1/4 Ounces) | 5″ x 7″ (12.7x 17.8) | 10×16.5+6cm | Suitable for personal use or small consumption |

| 14g(1/2 Ounces) | 6″ x 9″ (15.2 x22.9) | 13×20.5+8cm | Medium package for longer use |

| 28g(1 Ounces) | 7″ x 10″ (17.8 x 25.4) | 15×25+8cm | Large packages, typically for longer-term consumption or home use |

| 56g(2 Ounces) | 8″ x 12″ (20.3 x 30.5) | Larger package for wholesale or multiple users | |

| 112g(4 Ounces) | 9″ x 14″ (22.9 x 35.6 ) | For larger packages or bulk consumption |

4. Compliance with laws and regulations

Our marijuana bags comply with local laws and regulations, are made of food-grade materials, are safe and environmentally friendly, and have childproof zippers that can effectively protect children.

5. Choose economical and cost-effective bags

Different materials and printing methods will lead to different purchasing costs; we provide customized marijuana bags for our customers; there are two more common printing methods: digital and gravure printing.

For small buyers just starting, we recommend digital printing, which is suitable for customers who need smaller quantities and need to print their designs. If your budget is limited, you can also

If you have a limited budget, you can also consider labelling, which is more economical.

Of course, we recommend using intaglio printing for a certain number of customers; this printing is clear, and after the first time to do the plate, and then can be reused for a few years, a significant cost savings.

Gravure printing suits customers requiring high-quality printing with more than 5000 bags.

6. Selection of bag extras

We also offer our customers the option to add extra features to their cannabis bags, including UV protection, Spot UV, tactile film, Hot Stamping, Holographic, gloss, matte, embossing, and many other customer-preferred features.

Further, it enhances the customer’s packaging brand awareness.

Summarize

When choosing the right marijuana zipper bags, you must consider several factors to determine a comprehensive, less knowledgeable bag. Customers can always consult us for details on marijuana packaging, and our professional and technical staff will answer your questions.

Our professional technicians will answer all the questions customers want to know so that they can solve all their doubts about marijuana zipper bags.

Steps to Customize Weed Zippers

1. Clarify the need for a weed zipper bag

The customer first needs to define a few key requirements:

Weight of marijuana product to be packaged: e.g., 1g, 3.5g, 7g, 14g, or 28g.

Bag type: stand-up pouch, flat pouch, clear window pouch, child-resistant design pouch.

Functional Requirements: e.g., moisture-proof, UV protection, odor shielding, and easy pull closure.

Appearance design: whether to print Logo, brand information, transparent window, etc.

2. Selection of materials

Choose the suitable material according to the product characteristics:

Inner layer: food-grade aluminum foil or plastic, providing moisture-proof and odor-blocking functions.

Outer layer: Transparent or opaque plastic, supports printing design.

Special coatings:

UV protection coating: protects cannabis from light.

Odor Shield: prevents odors from escaping.

Eco-friendly options: such as biodegradable materials or recycled plastics.

3. Design and Proofing

Design draft preparation:

Determine bag size and shape. Prepare brand logo, graphics, and package information.

Create a design using a design tool (e.g., Adobe Illustrator or Photoshop), usually in a vector file format (e.g., .ai or .eps).

Proofing:

Give the design to the supplier and request a sample.

Check colors, sizes, sealing properties, etc., to ensure the sample meets expectations.

4. Confirm production details

Communicate the following information with the manufacturer:

Printing technology:

Flexographic printing: suitable for mass production.

Digital Printing: Suitable for small batches and diverse designs.

Minimum Order Quantity (MOQ): Determine if the factory supports your order quantity.

Delivery time: Confirm that the lead time is as expected.

5. Production and quality control

Production is divided into

Printing: presenting the complete package on the bag according to the designed file.

Laminating: Laminating the printed surface film with the easy-to-heat-seal inner film with the special adhesive high-speed webbing machine.

Curing after the composite is completed needs to be cured in a curing room above 45 degrees for more than 24 hours to make the marijuana zipper bags not easy to delamination.

Bag making: at this time, the production of marijuana zipper bags has entered the end of the bag. The technician must have certain skills, ensure that the color printing bags seal good air leakage, and the temperature control of the hot knife has a certain technical.

After the quality inspector inspects the factory

Mass production:

After the samples are correct, mass production will be launched.

Quality check:

Ensure that each batch of bags is well sealed, accurate in size, and printed.

Check the moisture-proof, oxygen-blocking, and light-proof performance of the bags.

6. Packaging and Delivery

We have long-term cooperation agreements with DHL UPS and many other international courier and logistics companies. Depending on the customer’s delivery date and the delivery method, various transportation modes are available, such as air freight, sea freight, and door-to-door.

Packaging: Large quantities of products are usually shipped in boxes to prevent damage during transportation.

Logistics arrangements:

For domestic orders, choose courier services or logistics companies.

International orders: Ensure the supplier supports the export process, including preparing customs documents.

7. After-sales service

We have good after-sales service. We will solve any problem immediately after customers receive the marijuana zipper bags, record any issues, and propose solutions based on customers’ feedback.

Ensure the customer’s marijuana zipper bags can well enhance the customer’s packaging brand!