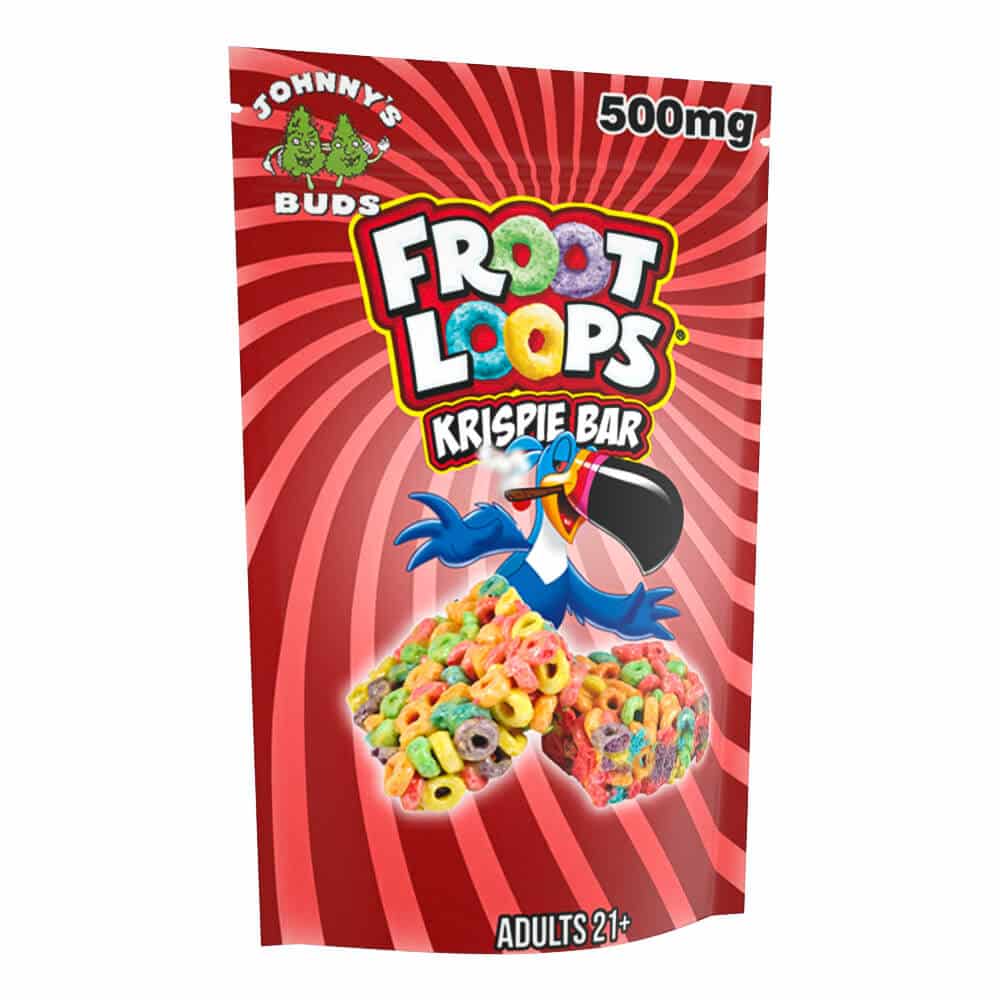

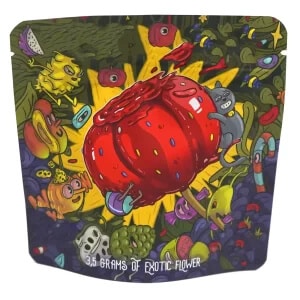

Custom mylar bags

Wholesale Mylar Bags for Food Storage, Freeze Drying. Odor-Proof Bags, Oxygen Absorbers, Desiccant and more. Free shipping, advice and information.

Custom Printed Mylar Bags bags factory

Ewaybag, a professional manufacturer specializing in bags with 20 years of experience, has been committed to providing packaging solutions for our customers. Especially in recent years, customers’ demand for weed packaging bags.

In increasing demand for food and pharmaceutical packaging, we continue to invest in research and development and purchase equipment to provide customers with customized packaging bag services. This is to enhance customer brand

This is of great benefit to enhance the brand awareness of our customers. Custom mylar bags keep the weed fresh and odor-proof and prevent odor seepage. More importantly, we prevent children from accidentally opening the design; we also have recyclable materials for customers to choose from, which are more environmentally friendly.

Various types of custom mylar bags

Custom mylar bag ziplock bags

Mylar bags are the ideal packaging for food.like: weed, snack, tea, powde.

Custom Shape Mylar Bags with Logo

Custom mylar bags with logos, pictures and letters.FDA Food Grade.

Advantages of custom mylar bags

Professional custom packaging bag

Professional packaging bags 20 years of wealthy manufacturers

With professional mylar bag designers

One idea, we’ll make it happen

free sample

Customer orders reach the quantity specified by the company and the

The initial sample fee is fully refunded

Fast delivery

With our professional packaging talents and equipment, we can

Delivery of custom mylar bags in just a few days

Low MOQ

Custom mylar bags can be delivered with a minimum order quantity of just a few hundred

Our digital printing technology is an excellent guarantee to achieve low MOQ

Good after-sales service

If you have any dissatisfaction during the order, we

have a dedicated service to solve all problems

Custom mylar bag process

Step 1.choose your bag type: stand-up pouch, flat bottom, three-side seal, center seal, etc.

MID-SEAL BAG

FLAT BOTTOM RESEALABLE BAG

SIDE STEREO-SCOPIC SEAL-ING BAG

FOUR-SIDESEALING BAG

TFLAT

BOTTOM BAG

RESEALABLE BAG

ROLL FILM

Step 2.Choose your material structure and thickness: PET, PE, VMPET, etc.

Plastic

Chemical stability, the sound barrier to water, oxygen, carbon dioxide, and various

Fiol

Extremely high puncture resistance, with good barrier properties, can block oxygen, light, water and sewage, water vapor

Kraft

Kraft paper is non-toxic, odorless, non-polluting, recyclable, and has anti-drop performance.

PET

Fatigue, abrasion, non-toxic, odorless, good hygiene, and safety can be directly used in food packaging.

PE

It has good chemical stability and can resist the erosion of most acids and alkalis, so it is widely used in refrigerated food packaging.

Laser

It has a novel and bright appearance, high-tech anti-counterfeiting function, and is beautiful and environmentally friendly.

Characteristics and applications of packaging bag materials

| material | material properties |

| BOPP | Good tensile strength, but low tear strength, good chemicalstability. aood water resistance. |

| CPP | Good transparency, good gloss, high stiffness, so the shelfdisplay effect of packaged goods is good, heat resistance,can be resistant to cooking more than 100℃. |

| BOPET | It has high tensile strength and is therefore one of the higher plasticfilm products.It has high barrier to air and odor and is one of thearoma-protecting materials. |

| BOPA | Tensile strength, tear strength,impact strength and rupturestrength are all good in plastic materials. |

| PE | A large variety of plastic film, good flexibility, high elongation, and low hardness |

| VMPET/VMCPP | High barrier film, excellent aroma retention and lightshielding, can prevent food oxidation spoilage. |

| EVOH | Has good gas barrier properties, fragrance retention and chemicalresistance for grease liquids and toxic volatile products |

| AL | Aluminum foil, good barrier material, impervious to light,moisture and air. |

| Material | Applications |

| BOPP/CPP; BOPP/VMCPP; BOPP/VMPET/PE | Snacks, cookie, candy, biscuit,nuts |

| BOPP/CPP; BOPP/VMCPP; BOPP/PE; BOPP/PET/PE; | lnstant Noodles, grain, seeds,Ordinary food packaging |

| Twist VMPET; Twist PET; PET/ALU/PE; BOPP/VMPET/PE | Candy, coffee, powder,good barrier and moisture proof |

| PET/VMPET/LLDPE; PET/PE;PET/ALU/PE; PET/NY/PE | Liquid juice, jelly, detergent,good flavorkeeping |

| PET/ALU/NY/PE; PET/NY/PE | Oil, sauce, spices, wine,for liquid packaging |

| PET/Kraft paper/PE; PET/Kraft paper/VMPET/PE | Coffee, tea, powder |

Step 3.Choose your size: width and length and corner gusset plate. (e.g. 102*127+50 mm)

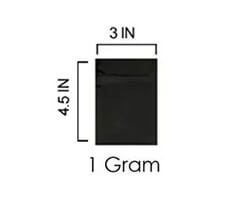

1 Gram

4.5inx3in

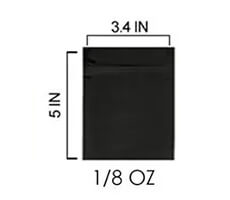

1/8OZ

5inx3.4in

1/4OZ

6.5inx4in

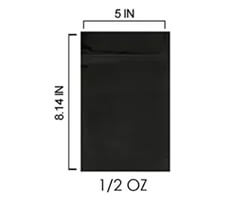

1/2OZ

8.14inx5in

1OZ

9.25inx6in

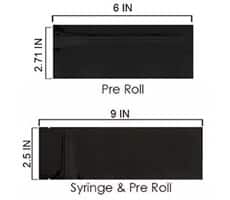

Pre roll

2.71inx6in 2.5in

Step 4.Choose your closure Re-closable/re-sealable zipper, Innolock zipper, or Velcro plus illustration

Seal tear strip

Easy to tear,

sealed and storedProduct storage ismore convenient;

T-shaped side zipper

lt can be openedrepeatedly, sealed continuously, tight andnot leaking;

One-way air valve

Prevent oxidation ,prevent bag bursting,Exhaust the carbondioxide released bythe coffee beans toavoid the peculiarsmell caused by theoxidation of the oil

Bottom can stand

Tightly sealed,independent andworry-free

Good edge bandingtechnology and round corner designto avoid scratchingyour hands

Step 5.Choose your add-ons Degassing valve or vent – Clear window – Tear opening Euro or round hanging hole – Spout with cover – Rounded corners

Clear window

Increase the aesthetic feeling, attract the public’s eyes, see the product through the window, and increase the desire to buy

Tear opening euro

Users can easily open the bag, convenient and durable

Rounded corners

Rounded corners can protect consumers, and arcs are the most friendly shape, which can reduce the aggressiveness of the product and make the product more visually accessible.

Spout with cover

Mylar Aluminum Foil Spout Pouches Flask Bag For Detergent,Shampoo

This range is suitable for Juice , water , Sauce , Liquid , beverage , cosmetic.

Round hanging hole

Portable hanging hole

Ergonomic handles

Step 6. Decorative colors glossy, matte or frosted finishes

Glossy

matte

frosted finishes

Soft touch

Gold Hot Stamping

Spot UV

Step 7.Choose your application: solid or liquid, food, etc.

Step 8.Choose your printing colors: how many colors are in your design. (If possible, please provide Pantone chroma or RGB)

Digital Printing 500 MOQ

Only 500 start prints Multi style,Zero edition fee,24 color printing without plate fee,One bag, one picture Variable data printing,Free membrane material sample Accurately grasp the color effect, 3-7 working days

Gravure Printing 5000 MOQ

The printing ink layer is thick, the color is bright, the saturation is high, the printing plate durability is high, the printing quality is stable, the printing volume is large, and the printing speed is fast.

Suitable for PE (HDPE, LDPE), PP, PET, PVC and other plastic films.

Step 9.Packaging bag Laminating

laminating the printed surface film with the easily heat-sealed lining film using a high-speed laminating machine with a unique adhesive.

Step 10.Packaging bag Curing

After lamination, it needs to be cured in a curing room above 45 degrees for more than 24 hours to make the food packaging bags not easy to delaminate.

Step 11.Bag-making

the bag-making technician must have specific skills to ensure that the color printing bag seals well and does not leak and the temperature control of the hot knife with a certain degree of technicality.

Step 12.Quality inspection

Quality inspector inspection after the factory, in the bag quality inspection, will be all the unqualified products in addition to do zero unable products factory, only the qualified products for packaging.