The material Options for our Packaging Bags

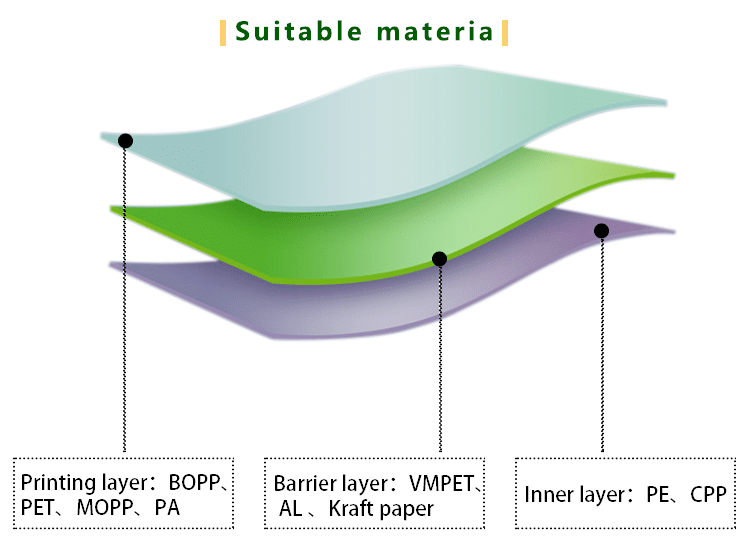

There are many types of materials used in packaging bags, including:

- Polyethylene (PE) – a widely used plastic for its durability, flexibility and low cost.

- Polypropylene (PP) – another common plastic used for its strength and resistance to high temperatures.

- Polyethylene terephthalate (PET) – a strong and lightweight plastic often used for food and beverage packaging.

- Nylon (NY) – a strong and durable material with high puncture resistance, often used for heavy-duty applications.

- Aluminum foil (AL) – a barrier material that is impermeable to light, moisture and gases, often used for food packaging.

- Paper (Kraft Paper) – a renewable and recyclable material often used for grocery and shopping bags.

- Cellulose – a biodegradable material made from plant fibers, often used in eco-friendly packaging.

- Biodegradable plastics – a type of plastic that can break down under certain conditions, often used for environmentally friendly packaging.

The materials usage in different types of packaging bags

1.High-temperature cooking bags and Vacuum bags

High-temperature cooking bags and vacuum bags are used for packaging various cooked meat products. They are easy to use and hygienic.

Materials include NY/PE, NY/AL/RCPP, and KNY/PE.

Features include moisture resistance, heat resistance, light blocking, fragrance preservation, and strength.

They are suitable for sterilized food, ham, curry, grilled eel, grilled fish, and meat products.

Typical structures for boiling bags are PET/PE, BOPA/PE, and PET/AL/PE. Features include withstanding sterilization at temperatures up to 106 ℃, high sealing strength, good puncture resistance, high impact resistance, good printability, and excellent oil resistance. They are used for packaging various boiled foods.

2.Stand-up Pouches

Stand-up bags are not easily deformed and can be placed upright. They are used for daily necessities (such as laundry detergent, fabric softener, and various supplements), pet food, food (such as puffed food, rice, dried fruits, chestnut bags, and boiling self-standing bags), and health products (such as tea, powder, and granules). Features include good stand-up performance, pressure resistance, leak resistance, impact resistance, and high-temperature resistance.

Materials for stand-up bags include ONY/LLDPE, PET/AL/LLDPE, PET/ONY/LLDPE, PET/CPP, ONY/CPP, PET/VMPET/LLDPE, OPP/VMPET/LLDPE, and other special materials.

3.Aluminum foil bags

Aluminum foil bags usually refer to aluminum-plastic composite vacuum packaging bags. They are suitable for moisture-proof, light-shielding, and vacuum packaging of large precision machinery equipment, chemical raw materials, and pharmaceutical intermediates.

They typically use a four-layer structure and have good water and oxygen barrier properties. Custom sizes and styles of packaging bags are available, including flat pouches, three-dimensional bags, and accordion bags. Products must pass GB and ASTM standards tests, meet environmentally friendly requirements (third-party test reports are available), and meet the strictest environmental standards for packaging materials in Europe and North America. High-density polyethylene plastic bags are used for food packaging (such as cakes, candy, fried foods, biscuits, milk powder, salt, and tea), fiber products (such as shirts, clothing, cotton needles, and chemical fiber products), and daily necessities.

4.Low-density polyethylene plastic bags

Low-density polyethylene plastic bags are used for garbage bags, spawn bags, convenience bags, shopping bags, handbags, vest bags, fresh-keeping bags, and woven inner bags. Polypropylene plastic bags are used mainly for packaging textile products, needles and cotton products, clothing, and shirts. Polyvinyl chloride plastic bags are used for gift bags, luggage bags, cotton needle packaging bags, cosmetic packaging bags, file bags, and document bags (with zippers).

What’s the difference between VMPET and AL?

VMPET Self-introduction

VMPET is the more suitable material for printing. Which helps to maintain the freshness of the coffee by keeping it free from moisture, oxygen, heat and light.

Traditionally, aluminium has been used in coffee packaging because of its ease of sealing, penetration and heat resistance, as well as for the preservation of the taste and aroma of coffee.

This option, however, is not flexible and is often costly. As a result, Vacuum Metalised Polyethylene Terephthalate (VMPET) is widely used.

VMPET is printed with a transparent, lightweight, polyethylene base material with superior mechanical strength.

This material is often used in the manufacture of plastic bottles. It can be molded into any shape and provides an appropriate surface to stick to.

In order to form with VMPET, PET is vacuum coated with a thin metal film, approximately 1/175 thick as the aluminium commonly used in aluminium lined packaging.

This produces metalised PET, giving it an aluminium foil look.

It’s an easy way to make VMPET when the manufacturer has advanced technology.

The process includes seven methods as following.

- Heating aluminium or other suitable metal, such as nickel or chromium, to its melting point.

- Being dissolved under a vacuum.

- The melted metal is concentrated and condensed on a clean surface of the PET material.

- The VMPET obtained is cooled and ready to be molded or printed.

VMPET against Aluminium

Aluminum is not as easily heat-sealed and may break when folded. Which means that it is the best choice to use multilayered laminate to resist rough handling.

But VMPET is made of only about 1% of aluminium in comparison with standard aluminium lined packaging. Which makes the VMPET more economical.

Incidentally, VMPET is a printer. Then, after being opaque, it reproduces the colours and contrasts them exactly. This will make your logo or art work visible and appealing to consumers.

Two sides of the same coin.

Compared with aluminium, the water vapour and oxygen penetration rates of the packaging are relatively high for VMPET. Which can cause problems because coffee is stored for a long time before it is drunk.

Therefore, VMPET is often used in multilayered packaging with LDPE (PE) to enhance its superior flavour and fragrance protection properties.

Different from kraft paper, VMPET composite bags are hard to recycle due to the structure of packing layers.

Even VMPET can compete with aluminium in multilayered packaging. But it’s not always the best option for all buyers.

If you sell large quantities of coffee or make long journeys. It’s best to have a long shelf life when you pack your coffee. Under these circumstances, it would be better to stick with an AL (aluminium) lining.

At the same time, you need to consider how your customers feel about your packaging.

Coffee packaging bag production process

Coffee packaging bags are an important part of the coffee industry.

The production process of coffee packaging bags involves several steps:

Step 1: Material selection

The first step is to select the appropriate material for the coffee packaging bag. Materials must be chosen based on their ability to protect the coffee from external factors such as light, moisture, and oxygen. Laminated films, such as PET/AL/PE and PET/VMPET/PE are commonly used for coffee packaging bags.

Step 2: Printing

Printing is the next step in the production process. This involves printing the design onto the laminated film. Printing can be done using both digital and traditional printing methods.

Step 3: Lamination

Once the design is printed, the laminated film is then laminated to ensure durability, excellent barrier properties, and proper seal strength.

The laminated film is treated with a coating of adhesive to create a strong bond between the layers.

Step 4: Bag making

After lamination, the film is then cut and sealed to create the coffee packaging bag. This is done using high-speed automated equipment that can produce bags in various sizes and shapes.

Step 5: Quality control

Quality control is an essential step in the production process. Quality control checks are performed at every stage of production to ensure that the bags meet the required standards for strength, durability, and barrier properties.

Step 6: Packaging and shipment

After the bags have undergone quality control checks and are deemed suitable, they are then packaged and shipped to coffee producers, distributors, and retailers.

In conclusion, the production process of coffee packaging bags involves several steps, including material selection, printing, lamination, bag making, quality control, and packaging and shipment. By following these steps, coffee producers can ensure that their bags are of high quality and effectively protect their coffee from external factors that could compromise its quality.

General Sizes & Materials Choices for our Coffee Packaging

A preference for smaller servings of coffee, we offer 70-gram quad seal bags made of Matt opp18/Vmpet12/Pe80 material that can hold approximately 2-3 cups of coffee. The bags have dimensions of 80 x 120 x 30 mm, and the minimum order quantity (MOQ) is 30,000 pieces.

If you require a larger bag, our 125-gram coffee bags are also made of the same Matt opp18/Vmpet12/Pe80 material and are equipped with a zip and a valve to keep the coffee beans fresh. The bags have dimensions of 90 x 185 x 55 mm, and the MOQ is 20,000 pieces.

For those who need even more coffee, we have a 250-gram pack made of Mattopp18/Vmpet12/Pe90 with a zip and a valve for freshness. The bag measures 120 × 195×65 mm, and the MOQ is also 20,000.

If that is still not enough, we offer five hundred gram and one-kilo coffee bags, both available in four sealed box bags with zipper and valves, made of Mattopp18/Vmpet12/Pe90 material. The 500g bag measures 135x265x75 mm, and the 1kg bag measures 145x335x100mm. Both have a minimum order quantity of 20,000 pieces.

Welcome to our store, we have a range of coffee bag sizes to cater to your specific needs, starting from 70 grams up to one kilogram.

Your packaging always be our concerns in heart. Your sincerely partner in long-term relationship EWAYBAG.