Various kinds of bags or pouches can be custom by Ewaybag Packaging.

Our stand-up bags are made of food-safe, heat-sealable materials.

There are a lot of shapes you can choose from when printing.

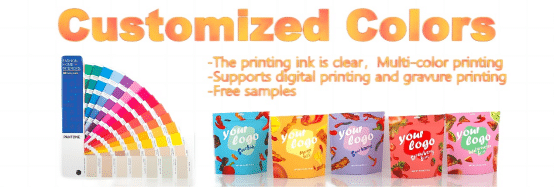

Custom printing is acceptable. Classical printing and stylish shapes will make your packaging attractive.

Hang holes and notches make displaying and using the bags easy.

High-quality, easy-to-tear design suitable for snack food manufacturers.

Classical Printing Methods in Plastic Packaging Design

How Are They Printed?

Flexography Printing

For the most part, the plastic bags were printed in different ways depending on the size of the press run.

For the longer runs, the more economical technique involved a large web press.

A roll of plastic (composed of two sheets, one atop the other) is held in tension by the press as the plastic sheet travels through a number of inking units. Research shows that flexography, not offset lithography, was the appropriate commercial printing method.

Flexography is a process in which the raised image area of rubber printing plates deposits ink on the substrate.

Unlike offset lithography, which uses flat, or planographic, plates.

The flexography plates are affixed to the press rollers with adhesive, as the rollers turn and the plates strike the ribbon of sheet plastic traveling through the web press, the plates print the graphic designs on the plastic.

This process allows for the printing of a number of colors but does not allow for a tight register of the colors as does offset lithography.

After the ribbon of sheet plastic has traveled through the press and has been rewound at the delivery end of the equipment, a post-printing step can be done in which the bags are cut off the single sheet of plastic (cutting at the top and bottom) and fused with heat (at the top, bottom, and sides), creating a plastic bag.

Screen Printing

For short Print Runs of Plastic Bags

A platen press is a letterpress where a round “platen” (pressure plate) comes down onto the equipment’s bed to press inked plates against the plastic bags.

One color was printed at a time and the process was slow.

Screen Printing on Plastic Bags

Unlike the web of uncut plastic used on the flexography presses, the screen-printing option showed the custom screen-printing operator placing an individual bag around a wide, flat support structure, not unlike an ironing board (also called a “platen”). This kept the bags stable as the operator lowered the metal screen onto the bag and dragged the squeegee and ink across the screen. The platen letterpress seemed to be a labor-intensive process, which was only good for short runs of the bags, printed with only a few colors.

Inkjet Printing

The usage of inkjet printers with plastic bags, although this technology seemed to be more appropriate for imprinting tracking numbers than for printing graphic images.

Most printers would produce bags within a limited palette of “standard” colors. or an additional fee, however, they would mix a PMS color.

Printing on Paper Grocery Bags

Brown paper grocery bags are composed of a single, thick sheet of Kraft stock printed on custom screen-printing equipment.

Operators were printing the bags by hand one at a time, laying the open bags over a “platen” (the flat, ironing board-like structure), and then lowering the screen and applying ink through the screen with a squeegee.

Gravure Printing

The ink-receiving part of the gravure printing plate is concave, so it can accept a large amount of ink. If it is used in conjunction with the electrostatic ink-absorbing device on the gravure printing machine, it can obtain a rich ink layer, bright colors, and rich colors. level.

Relatively low cost Since the entire layout of the gravure printing plate is protected by a hard metal chromium layer, even if there is a scraper in constant contact with the layout during printing, it still maintains a high printing resistance, generally up to several million prints.

Offset printing wraps the finished printing plate on the printing plate cylinder, therefore, there is always an area on the surface of the printing plate for fixing the printing plate. The gravure printing plate is different because the plate-making operation of the gravure printing plate is carried out directly on the cylinder body, so the images on the cylinder do not need to be seamlessly spliced, and a continuous pattern can be obtained on the substrate.

Gravure printing can be printed on traditional paper, but also on film, aluminum foil, transfer paper, and other materials.

Multiple Types of Printing Applications

Printing on Luxury Department Store Paper Bags

The high-end department store bags were printed in two different ways.

One is an automated screen press turning a pre-made high-end department store bag over to allow the ink screen and squeegee access to either side of the paper bag. This was for a simple design screen printed in one color.

For more complex design printing work, the bags are initially offset printed on flat press sheets and then die cut, folded, and converted into laminated bags with the exterior paper stock folded over the edges of the bags and pasted into their interior.

These often have specialized rope or fabric handles affixed to the bags through die-cut holes. As with other offset press work, various coatings, hot-stamp foils, and embossing effects can be used.

In some cases, an additional layer of paper covers the interior of the bags.

Packaging printing is a creative artwork by highly skilled commercial printing establishments.

Flexible packaging design printing process

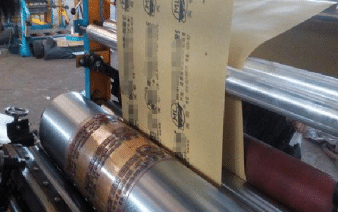

(Plate roll printing)

Flexible Packaging:

The popular understanding is “bag packaging”. Flexible packaging refers to packaging in which the shape of the storage container can change after filling or removing the contents.

All kinds of packaging bags, packaging boxes, protective sleeves, plastic seals, etc. made of aluminum foil, fiber, paper, and plastic film and their compounds can be called flexible packaging.

Plate roller: popularly understood as “steel pillar carved with pictures and text”. Just because the word “version” doesn’t mean it’s flat. “Roll” refers to a cylindrical part on a machine that can rotate.

The plate roller, also called the steel roller, is a roller, generally used for plate making, the surface of the roller is plated with copper, the pattern is engraved by a gravure electronic engraving machine, and then a layer of chrome is plated, and the plate roller factory is delivered to the packaging material factory for printing.

The following is a printing process for flexible packaging design manuscripts:

STEP 1 packaging layout design finalized (provided by customer).

STEP 2 roll mill receives the design file (typically in I/EPS/CDR/PSD format) and processes it.

The plate roller factory will confirm the document’s spot color, color registration, overprinting, bleeding, and other information, so as to make the design manuscript sent by the designer into a TIFF (Tag Image File Format) file with a recognizable spot color channel.

STEP 3 proofing. The plate roller factory prints out the paper manuscript of the adjusted TIFF file, and sends the paper draft back to the designer for layout effect verification.

STEP 4 version roll making. After the paper manuscript is checked, the plate roller factory carries out imposition, printing plate, trial engraving and other processes to complete the plate roll production, and the production cycle of the plate roller is usually 5-7 days (this cycle is obtained from the experience of cooperation with some plate factories, for reference only, not unique). If a manuscript is printed in several colors, several plates will be made.

For example, if my design has a PANTONE 2347C, a gold ink, and an illustration pattern, without other specific spot colors and processes, how many plates will be used in the manuscript?

4+2+1=7 branches

4 fingers CMYK four colors, colorful illustration four inks are essential

2 refers to spot color 2347C and gold ink version

1 refers to the white version

Why is there an extra white version? First of all, white ink can cover the background color or material color, ordinary materials such as white card, copperplate, writing paper printing does not need white ink, but when encountering gold card, silver card, colored special paper or other materials, it needs to be used. It is also used in small details that are not noticed, such as the QS mark and the white background color of the barcode.

If you do not want to suffer losses, the designer must be cautious and cautious when checking the paper manuscript transmitted back by the plate factory to avoid plate making errors. Plate making errors, after entering the printing process is extremely difficult to remedy, can only be remade, monochrome single plate price ranges from hundreds to thousands of yuan.

STEP 5 rolls are finished and sent to the packaging mills. In order to ensure that the printing effect meets the requirements of the designer as much as possible, the packaging material factory will also need to proofread the paper manuscript for comparative printing.

STEP 6 printing. The technician compares the paper manuscript and color information to bring up the required ink, which is printed layer by layer and then printed on the substrate. Designers with high printing requirements can go to the packaging material factory in person to perform on-site color correction.

STEP 7 bags. After printing, wait for the ink to dry, and start composite bag making. Composite is simply to paste the substrate with other materials (paper, film, etc.), the composite methods include dry, wet, extrusion, hot melt, multi-layer extrusion, etc., and the composite packaging material is a complete packaging bag material.

Once the bag is made and filled with contents, it is a perfect product.

Feel free to contact us to get your unique artwork.

Your sincere supporter EWAYBAG