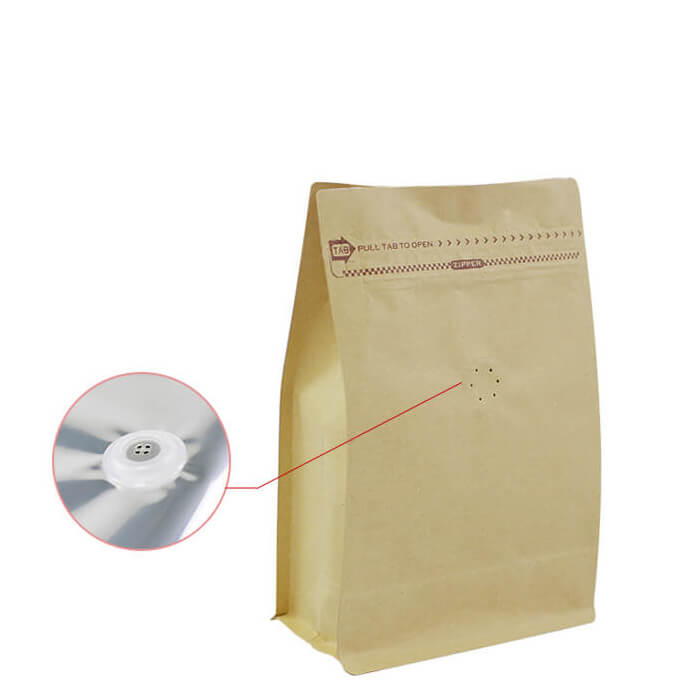

The role of the degassing valve

The coffee bag’s exhaust valve uses the one-way exhaust principle so that the gas inside the bag can be discharged and isolated from the external gas.

So why is it necessary to vent the gas inside the bag? Because the roasting process will cause the coffee beans to produce a lot of carbon dioxide, the beans will continue to exhaust after the roasting process, which is why freshly roasted coffee beans will have a lot of bubbles when brewed.

And the more profound the roast, the more pronounced the outgassing. Most coffee factories have a vast production volume; there is no time and space to wait for the beans to exhaust; it will be immediately after the end of roasting for packaging; continuous exhaust may burst the bag, so install a one-way exhaust valve to let the beans in the bag to complete the process.

1, as the coffee beans, after roasting, will produce carbon dioxide, this air valve can be carbon dioxide out of the bag, in addition to blocking the oxygen outside the bag into the bag inside the oxidized beans, thus ensuring the new quality of coffee and eliminating the risk of the resulting coffee bag bulge expansion or burst.

2, after roasting the coffee beans will naturally emit carbon dioxide (CO2), such as accumulation in the bag will affect the quality of the coffee beans. The load on the exhaust valve on the ventilation holes can let the bag excess gas discharge, and the purchase of coffee can squeeze the bag smell, so customers can better confirm the freshness of coffee (quality).

3, coffee bags “exhaust valve” ventilation holes can be isolated outside the bag of light and air intrusion so that the coffee beans can be in the best state of preservation packaging to maintain the freshness of the original flavor of coffee seeking

What is a degassing valve?

A vent is a one-way vent that allows the coffee beans and grounds to slowly release carbon dioxide (CO2) and other volatile gases from the bag without coming into contact with the outside air.

When coffee is roasted, many chemical reactions occur. Volatile gases, mainly carbon dioxide (CO2), are formed inside the beans. These gases add flavor to the coffee, but the problem is that they continue to be released for some time. After roasting, the accumulated carbon dioxide (CO2) leaches slowly (mainly within a few days). But it can take several weeks for it to all disappear. The valve has two essential goals: to allow the release of carbon dioxide (CO2) and to prevent the entry of oxygen. This process prevents oxidation and extends shelf life.

How the coffee one-way exhaust valve works

When sealed in the bag of coffee beans produced by the carbon dioxide gas so that the bag reaches a certain pressure, the gas can be pushed from the inside to the outside of the exhaust valve piece, causing outward discharge of excess gas; when the pressure inside the bag decreases to not enough to open the valve piece of the valve automatically closed.

Only in the bag pressure is higher than the pressure outside the bag will the valve automatically open, and vice versa will not open; the outside air can not enter the bag.

Why is carbon dioxide still present in roasted coffee beans?

Freshly roasted coffee is full of vitality, reflected in the coffee extraction, where the coffee beans are so full of gas that they expand at the slightest contact with water. The coffee undergoes many different chemical reactions during the roasting process; the complex carbohydrates are broken down into smaller molecules, the beans start to turn brown, and a lot of water vapor and carbon dioxide are produced; this is when the so-called “holes in the coffee bag” come into play.

Coffee bean bag on a small hole for the one-way exhaust valve because roasting coffee beans, its own will release carbon dioxide; if not installed one-way exhaust valve will cause the bag, and in severe cases, even cause the bag to blow up one-way exhaust valve oxygen is not into the inner bag. Excess gas can be discharged through it.

Coffee beans’ carbon dioxide put away or stay? What is the role of the coffee venting valve generation?

After the coffee beans are roasted, fresh coffee beans will also spit out carbon dioxide gas, especially deep-roasted coffee beans; the exhaust is quite exuberant, exhaling the gas, coffee beans will slowly bulge the bean bag; if the coffee beans raised beans fully sealed will lead to excessive expansion of the coffee bean bag, so will buy one-way exhaust valve bean bags to package coffee beans, so that the gas is discharged.

But the one-way vent valve on the market varies in quality and poor quality exhaust valve; in addition to the gas discharge inside the bag, the oxygen outside will also enter the coffee bean bag; once the oxygen contacts the coffee beans, it will begin to age, the freshness will decline.

To avoid the risk of premature aging of the beans in contact with oxygen, you should choose a bag without an air vent to do the best preservation of coffee beans, beans in the roasting is completed, when fresh into the bean bag immediately sealed, in the unopened state, you can check the freshness of the coffee through the appearance of the bean bag has not bulged, but also can effectively maintain the coffee aroma.

How to maintain the best flavor of coffee beans?

Coffee bean exhaust is said to be sealed exhaust; there is said to be open air exhaust; in fact, just roasted beans need to maintain proper contact with the air within a certain period; not well-raised coffee beans in the flavor will have defects, this feeling, like following a person who has not yet woken up to talk, looking at each other sleepy eyes like, will be very uncomfortable, and lose the desire to communicate.

So just roasted coffee beans to exhaust a few days? The length of time to vent depends more on the degree of roasting and extraction method; the roast is shallow, the use of utensils to extract the coffee, generally raised for 1 to 3 days can be, the roast is more bottomless, the use of an espresso machine extraction, it is necessary to increase 3 to 5 days of time.

Well-raised coffee beans should be sealed and stored as soon as possible; as the saying goes, red is easy to grow old, flowers are not red for a hundred days, and so are coffee beans. Coffee beans at the peak of the flavor stage generally only last 2 to 3 weeks, at most not more than one month, so we can also think that the freshness of coffee beans is one month, so it is recommended that you can choose to preserve the coffee beans on the bean bags without exhaust valves or choose to preserve the sealed cans, to extend the aroma of coffee Oh!

The importance of degassing valve for coffee packaging

Now, let’s delve into the three main reasons why degassing valves are so important.

The degassing valve helps the coffee package retain its shape by allowing gas to escape. Gases are released after roasting and will continue to be released even after the coffee has been packaged. Gas trapped inside the package can cause the bag or pouch to expand or swell. Not only does this look bad, but it can eventually cause the container to burst or leak. The venting valve allows the gas to go outside the pouch.

Maximizing FreshnessThe vent valve helps keep coffee fresh by allowing volatile gases to escape the bag while preventing other gases from entering the package. The main? Oxygen. When coffee is exposed to oxygen for extended periods, it can deteriorate, shortening its shelf life and negatively impacting flavor. Therefore, a valve prevents oxygen from entering.

Improves packaging efficiencyThe use of degassing valves allows brands to package coffee quickly instead of waiting for all the gas to be released, thus increasing the efficiency of the packaging line. In this way, the coffee can be packed immediately, knowing that the degassing valve will allow all the gases to escape in a way that will not damage the packaging or the coffee itself.

Types of coffee packaging

(1). Bagged.

Bags are generally divided into non-gas-tight packaging, vacuum packaging, one-way valve packaging, and pressurized packaging. Non-gas-tight packaging.

It is a temporary packaging, which is only used for a short period of storage. Vacuum packaging.

The roasted coffee beans need to be placed for some time before packaging to prevent carbon dioxide damage to the packaging; this type of packaging can generally be stored for about ten weeks.

One-way valve packaging.

A one-way valve on the bag allows the carbon dioxide produced to be removed. Still, it prevents outside gases from entering, ensuring that the coffee beans are not oxidized but not preventing the loss of aroma.

This type of packaging can be stored for up to 6 months. There are also some coffee using vent packaging that is only in the bag on the exhaust hole without a one-way valve, so that once the carbon dioxide produced by the coffee beans is empty, the outside air will enter the bag, causing oxidation, so its storage time is significantly reduced.

Therefore, its storage time will be significantly reduced.

Pressurized packaging.

After the coffee beans are roasted, they are quickly vacuum-packed and sealed with inert gas.

This type of packaging can ensure that the coffee beans will not be oxidized and that the aroma will not be lost, but it also has enough strength to ensure that the packaging will not be damaged by air pressure and can be stored for up to two years.

Our coffee bags can also be divided into three side seals, stand-up pouches, eight side seals, and other bag types; we provide customized coffee bag services, including customer badges, logos, and printing patterns, which can be customized to improve significantly customer coffee brand awareness.

(2). Cans.

Cans – generally metal and glass- have plastic lids for air tightness. Instant coffee packaging

Instant coffee packaging is relatively simple, generally using small sealed bags, mainly in long strips, in addition to the outer packaging box.

Of course, a part of the market uses cans of instant coffee supply.

Handling of broken coffee bags

When the bag of packaged coffee is broken, air can enter the bag at will. The air contains moisture, which can quickly deteriorate the coffee in the bag. Therefore, you should use the clip to hold the coffee immediately after you find the coffee belt broken.

When you find the coffee belt broken, you should immediately clamp it with a clip to the ruptured place so that the coffee can be preserved for a few more days. If you want the coffee to have a longer shelf life, you need to replace the bag with a new one or replace the coffee in the bag with a new sealed jar, such as a glass jar or a metal jar.

This will preserve our coffee for a more extended period.

Canned coffee vs bagged coffee

1, Storage and Preservation

Canned coffee is more durable and stable than bagged coffee, which effectively protects the quality of coffee beans and reduces the impact of external factors such as oxygen and humidity, thus extending the shelf life of coffee.

The shelf life of bagged coffee is relatively shorter, but the bag can be installed with an exhaust valve, which is also conducive to maintaining the coffee’s taste and flavour.

2,Portability

In contrast, bagged coffee is lighter, easier to carry and suitable for travelling or office use.

Canned coffee is heavier, and you must pay attention to placement and handling during use.

3,Packaging

Canned coffee and bagged coffee are different in appearance and packaging.

Canned coffee is usually made of metal or plastic, with brand logos and information on the origin of the coffee beans printed on the surface, which has a high degree of aesthetics.

Bagged coffee is usually composite printed or three-dimensional bags; the appearance is not as good-looking as canned coffee, but more flexible and convenient packaging.

4, the price and type

Generally speaking, the price of canned coffee is slightly higher than that of bagged coffee. Still, the price difference is also relatively significant due to the many different brands and product categories.

Canned coffee is mainly oriented to the high-end market, and the variety is relatively single; while bagged coffee is rich in style and suitable for different people’s taste needs.

Professional China coffee bag packaging manufacturer

As a manufacturer of coffee bags for 20 years, we provide custom coffee bag service for our customers. Let the customer’s coffee beans and coffee powder packaging highlight the personalized and improve brand awareness.

Recommended bag types:

Stand-up pouches

Stand-up pouches with zipper

Stand-up pockets with bottom

Automatic packaging film

Three-side seal pouches

Medium-side seal pouches

Shaped bags

Material: According to the customer’s specific requirements, OPPICPP; OPPILDPE; PETALPE; PETNMPETIPE; PETPE; PETICPP; meanwhile, we can do transparent on one side and aluminized on the other side, etc.

Thickness: According to the customer’s requirements, 0.045mm—0.150mm thickness can generally be chosen.

Printing: We have many high-speed computerized color register printing machines to ensure the accuracy of the color register, and the printing effect can be assured.

Summarize

The coffee bag valve can ensure the coffee is fresh enough for customers to enjoy quality coffee. The exhaust valve of the coffee bag ensures that water and oxygen are isolated, and one-way elimination of carbon dioxide in the bag

This ensures the freshness of the coffee. Therefore, coffee bags with valves are one of the ideal choices for our customers. We also have coffee bags without valves and recyclable and degradable coffee bags that offer

customized printing services to showcase the client’s coffee bag brand better.