How should food packaging bags be classified?

Packaging can be categorized according to its role in the circulation process, the form of the packaging structure, the type of material, the packaged product, the object of sale, and packaging technology.

(1) According to the role of packaging in the circulation process can be divided into sales packaging and transportation packaging. Sales packaging, also known as small packages or commercial packaging, not only plays a role in protecting goods but also pays more attention to the promotional and value-added functions of commodity packaging, which can be integrated into the packaging design means to set up a commodity and corporate image, to attract consumers. Improve the competitiveness of goods. Bottles, cans, boxes, bags, and their combination of packaging generally belong to the sales package. Transportation packaging, also known as large packaging, typically requires a better protection function. Convenient storage and transportation, loading and unloading functions on the outer surface of the product instructions, storage and transportation, and other precautions of the text description or illustration. Corrugated cardboard boxes, wooden boxes, metal drums, pallets, and containers belong to the transportation packaging.

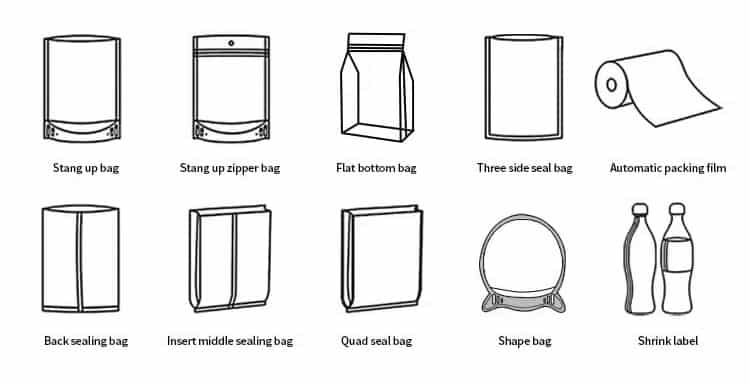

(2) According to the form of the packaging structure, packaging can be divided into sticker packaging, blister packaging, heat shrink packaging, portable packaging, pallet packaging, and combination packaging.

(3) According to the packaging materials, including paper and cardboard, plastic, metal, composite materials, glass ceramics, wood, and other materials.

(4) According to the packaging products, packaging can be divided into food packaging, chemical product packaging, toxic substances packaging, broken food packaging, flammable packaging, crafts packaging, home appliances packaging, miscellaneous products packaging, etc.

(5) According to the sales object, packaging can be divided into export packaging, domestic sales packaging, military packaging, and civilian packaging.

(6) According to the packaging technology, packaging can be divided into vacuum inflatable packaging, controlled atmosphere packaging, deoxygenation packaging, moisture-proof packaging, soft can packaging, aseptic packaging, thermoforming packaging, and heat shrink packaging—cushioning packaging, and so on.

The classification of food packaging is also as follows: according to the different packaging materials, food packaging can be divided into metal, glass, paper, plastic, composite materials, etc.; according to the various forms of packaging, food packaging can be split into cans, bottles, packages, bags, rolls, boxes, boxes and so on;

According to the different packaging technologies, food packaging can be divided into cans, bottles, packages, bags, and parcels, as well as filling the whole set, sealing, labeling, coding, and so on;

According to the different levels of products, food packaging can be divided into inner packaging, secondary packaging, tertiary packaging, outer packaging, etc.; according to other techniques, food packaging can be divided into moisture-proof packaging, waterproof packaging, mildew-proof packaging, preservation of freshness packaging, quick-freezing packaging, breathable packaging, microwave sterilization packaging, aseptic packaging, inflatable packaging, vacuum packaging, deoxidation of the packaging, blister packaging, sticker packaging, stretch wrapping, steaming bag packaging and so on.

All of the above packaging is made of different composite materials; its packaging characteristics correspond to the requirements of other foods and can effectively protect food quality.

Different foods should be based on the food characteristics of the other material structures of the food packaging bag. Then what kind of food is suitable for what kind of material structure as a food packaging bag? Today, to explain the need for customized food packaging bags, customers can refer to 1—steam cooking bags.

Product requirements: for meat, poultry, and other packaging, a packaging barrier is required, good resistance to bone holes broken in the cooking conditions of sterilization, does not break, does not crack, does not shrink, and has no odor. Design structure: Transparent: BOPA/CPP, PET/CPP, PET/BOPA/CPP, BOPA/PVDC/CPP, PET/PVDC/CPP, GL-PET/BOPA/CPP Aluminum foil: PET/AL/CPP, PA/AL/CPP, PET/PA/AL/CPP, PET/AL/PA/ CPP reason: PET: high-temperature resistance, good rigidity, good printability, strength. Pa: high-temperature resistance, strength, flexibility, good barrier properties, puncture resistance. A: best barrier properties, high-temperature resistance. Cpp: for a high-temperature cooking grade, good heat sealing, non-toxic and odorless. PVC: high-temperature barrier material. Gl-pet: ceramic vapor-coated film, good barrier properties, transmissible microwave. For specific products to choose the appropriate structure, transparent bags are mainly used for cooking; AL foil bags can be used for ultra-high-temperature cooking.

- puffed leisure food bags

Product requirements: oxygen barrier, water barrier, light, oil, incense, the appearance of quiet scratch, bright colors, low cost. Design structure: BOPP / VMCPP reason: BOPP and VMCPP are quite scratchy; BOPP has good printability and high gloss, and VMCPP has a sound barrier, keeping the aroma and moisture barrier. CPP oil resistance is also better

- Biscuit packaging bag

Requirements: Good barrier property, strong shading, oil resistance, high strength, odorless and tasteless, packaging quite scratchy. Design structure: BOPP/EXPE/VMPET/EXPE/S-CPP Reason: BOPP rigidity, good printability, low cost, VMPET sound barrier, light barrier, oxygen barrier, water barrier, S-CPP low-temperature heat sealing, good oil resistance.

- Milk powder packaging bag

Product requirements: long shelf life, aroma and flavor, anti-oxidation deterioration, anti-humidity caking. Design structure: BOPP/VMPET/S-PE reason: BOPP has good printability, good gloss, good strength, moderate price, VMPET sound barrier, light, good toughness, with a metallic luster to enhance the PET aluminizing is good, AL layer thickness, S-PE anti-pollution sealing, good low-temperature heat sealing properties.

- Green tea bags

Product requirements: anti-deterioration, anti-color, anti-flavor, that is, to prevent oxidation of green tea contained in the protein, chlorophyll, catechuic acid, vitamin C class. Design structure: BOPP/AL/PE, BOPP/VMPET/PE, KPET/PE Rationale: AL foil, VMPET, and KPET are excellent barrier materials; oxygen, water vapor, and odor barriers are sound. Ak foil, VMPET light avoidance is perfect. The price of the product is moderate.

- Ground coffee bags

Product requirements: anti-absorption, anti-oxidation, resistance to the product’s hardness after vacuuming, preserving the volatile, easily oxidized aroma of coffee. Design structure: PET/PE/AL/PE, PA/VMPET/PE Rationale: AL, PA, VMPET barrier is sound, water and gas border, PE heat sealing is good.

- Chocolate bags

Product requirements: sound barrier, light protection, beautiful printing, low-temperature heat sealing. Design structure: pure chocolate, varnish/ink/white BOPP/PVDC/cold sealing glue, chocolate nuts, varnish/ink/VMPET/AD/BOPP/PVDC/cold sealing glue, reason: PVDC, VMPET are high barrier materials, cold sealing glue can be sealed at a very low temperature, the heat does not affect the chocolate, due to the nuts contain a lot of oil, easy to oxidize and deteriorate, therefore, increase the oxygen barrier layer in the structure. Because the nuts contain more oils and fats, they quickly rot and decay, so an oxygen barrier layer is added to the system.

How to choose a good food packaging bag?

Choosing good food packaging bags is crucial to keeping food fresh and safe. Different types of food require different types of bags, and choosing the right food packaging bag also takes into account factors such as material, size, sealing performance, and environmental friendliness. Here are some suggestions for choosing good food packaging bags:

1.Material selection:

The material of food packaging bags directly affects the quality and safety of food. Common food packaging materials include plastic, paper, aluminum foil, etc. According to the characteristics of the food, it is crucial to choose the suitable material.

- Plastic bags: suitable for packaging dry, solid food, such as potato chips, candy, and so on. It is important to choose food-grade plastic bags that meet food safety standards to ensure no harmful substances are released.

- Aluminum foil pouches: suitable for packaging foods that need to be insulated from oxygen and light, such as coffee and tea. Aluminum foil bags have a sound oxygen barrier and a light barrier.

- Paper bags: suitable for packaging dry food, such as flour, cereals, etc.. Ensure that the paper bag has a certain degree of oil resistance to prevent food contamination in contact with the bag.

2.Sealing performance:

The sealing performance of food packaging bags is directly related to the degree of food freshness. Good bags should effectively block the entry of air and moisture, slowing down the rate of food spoilage.

- SELF-SEALING BAGS: Self-sealing bags have a convenient sealing function and do not require additional sealing equipment. It is suitable for lightweight foods such as nuts and vegetables.

- Heat-sealable bags: Heat-sealable equipment is needed for sealing, but its sealing performance is better, suitable for food that needs to be kept fresh for a long time, such as meat, seafood, etc.

3.Size selection:

The bag size should be selected according to the quantity and size of the food. Too big a bag will waste material; too small a bag can not hold the food and affect the sealing effect.

- Customizable size: If your food specification is more special, you can choose the customized size of the bag to ensure that the bag fits the food closely.

- Re-sealable:

Choosing re-sealable food packaging bags can help consumers open and close the bags conveniently, reducing food waste.

- environmental performance:

More and more consumers are concerned about environmental issues, and choosing environmentally friendly food packaging bags can help to enhance the brand image.

- Biodegradable materials: Choosing food packaging bags of biodegradable materials can help reduce environmental pollution.

- Recyclable materials: Prioritize recyclable materials to reduce the consumption of resources.

6.Safety certification:

Ensure that the selected food packaging bag meets the relevant national food safety certification standards, such as FDA certification (U.S. Food and Drug Administration).

7.Printing quality:

If you plan to print brand information or food labels on the bags, ensure the printing quality is good, the words are clear, and will not be blurred due to friction or environmental impact.

8.Cost considerations:

When choosing food packaging bags, in addition to considering quality and functionality, you also need to consider the cost factors to ensure that the cost of packaging is reasonable.

To summarize, choosing a good food packaging bag requires careful consideration of the material, size, sealing performance, environmental performance and safety certification, and other factors. According to the characteristics of the food and the positioning of the brand, choosing the right bag helps to enhance the image of the food and sales results, but is also conducive to environmental protection.

Summarize

We are a professional manufacturer of food packaging bags, providing customers with various customized food packaging bag services, including candy bags, cookie bags, vegetable bags, coffee bags, and so on. Our bags are customized and produced according to the customer’s needs, which can be better.

Enhance the customer’s product visibility. Good after-sales service can pack customers to rest assured that they can produce with us, and the excellent quality of the bags also provides consumers with a better visual and product protection experience.